Levi Strauss & Co. (LS&Co.), one of the most popular clothing

brands in the world, has long been committed to ensuring a sustainable supply

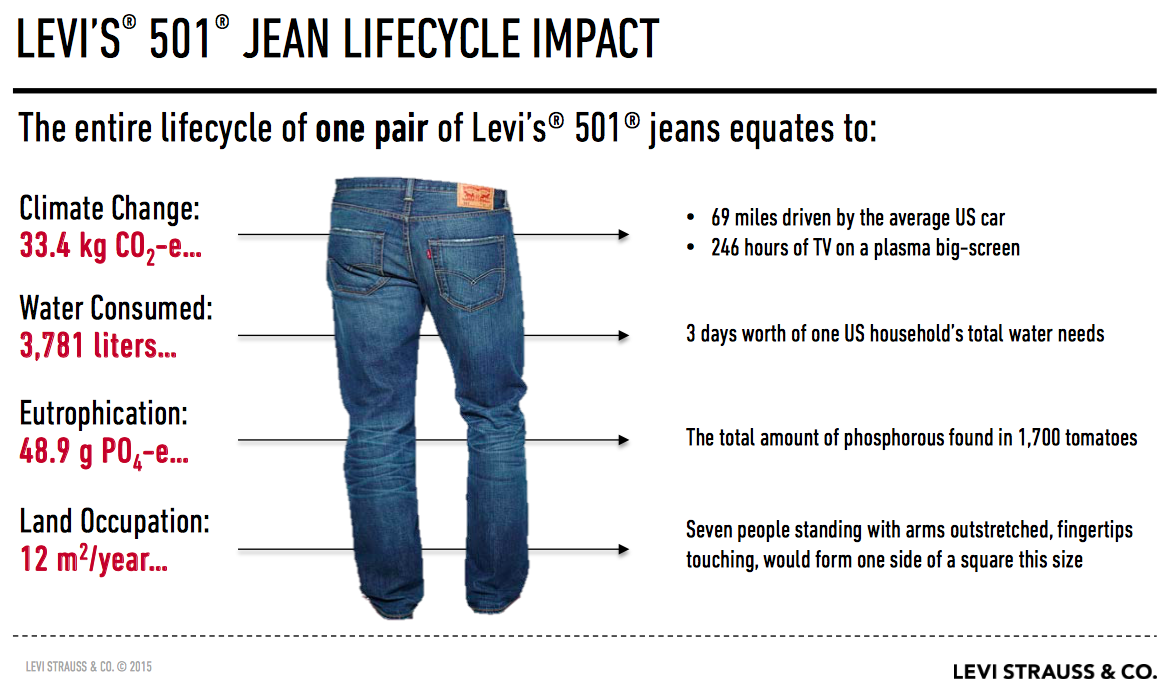

chain. The company conducted a comprehensive lifecycle assessment of a pair of

Levi's® 501® jeans in 2007 and again in 2015, gathering data related to water,

climate and chemicals at each stage of life of the product. It has used that

data to ensure sustainability at each stage of the supply chain, from cotton

growing to manufacturing and consumer care.

Through the lifecycle assessment, LS&Co. saw an opportunity to reduce

energy and water use together with its supplier partners.

LS&Co.'s official site states that it developed a series of innovative techniques,

called Water<Less™, which can save up to 96% of the water in the denim

finishing process. Since it was launched in 2011, Water<Less™ has saved 1

billion liters of water. Furthermore, 30 million liters of water were saved

through the industry's first Water Recycling

and Reuse Standard, which was pilotedwith one of LS&Co.'s

Chinese suppliers.

Recently, Levi's has made

its water reduction standards and tools, including the Water<Less™

innovations, publicly available to other industries, and

encouraged them to apply them. By utilizing the Water<Less™ innovations, the

apparel industry could save at least 50 billion liters of water by 2020. Levi's

goal is to produce 80% of its products with these techniques by 2020. Levi's

also extended its Global Effluent Requirements to textile mills in its supply

chain to ensure their focus on reducing water impact.

The person in charge of the company's energy-saving efforts related to its supply

chain in China explains:

"In China, the company partnered with NRDC and has participated

in the Clean by Design initiative since it launched in 2009.

Through Clean by Design, NRDC works with Chinese

mills to identify practical, low-cost and cost-saving opportunities to increase

operational efficiencies, while reducing materials, water and energy use and

decreasing waste and emissions. The initiative seeks to spread best practices

by convening the mills to share experiences and demonstrate how simple and

inexpensive changes can yield sizable impact.

Six mills

supplying fabric to LS&Co. participated in the Clean by Design initiative

between 2011 and 2015 and achieved significant success when it comes to saving

water and energy. These suppliers saved a total of 57,465 tons of steam, 366.6

million liters of water and 2.62 million KWH per year over the five-year

period.

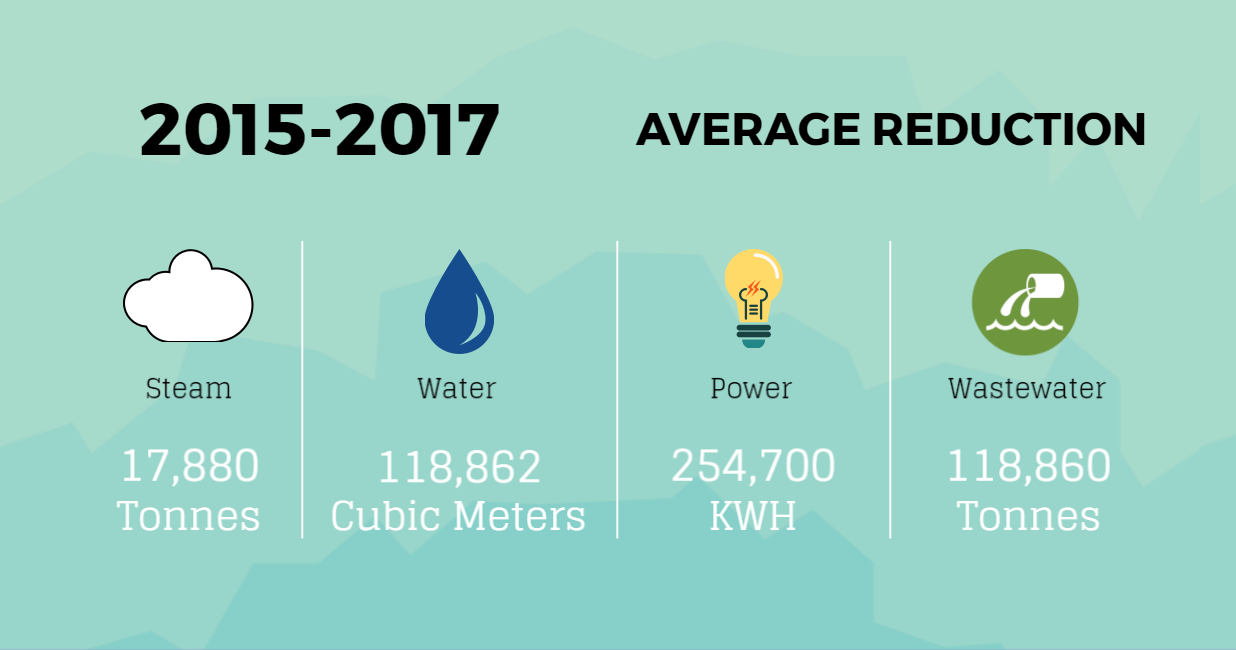

By 2016,

Clean by Design was in its third phase of program implementation in China,

which included collaborating with the Sustainable Apparel Coalition (SAC) to

use the Higg Index as a tool to measure environmental and energy performance.

At this stage, LS&Co. added two additional suppliers to the program to

reach a total of eight participating suppliers. Between 2016 and 2017, the two

suppliers saw savings of 17,880 tons of steam, 118,862 m3of water,

0.2547 million KWH, and reduced their wastewater discharge by 118,864 tons of

water.

LS&Co.

is committed to ensuring its suppliers reduce their overall environmental

impact. By working in partnership with its suppliers and encouraging them to

implement operational efficiencies, the company is helping build a responsible

workplace for the benefit of all."

Besides, as of July 2017, LS&Co. has also pushed 83 suppliers in China

to publish 141 PRTR forms on IPE's website, covering energy and water

consumption data as well as wastewater discharge, air emissions and solid waste

data.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)