Mitigating water risks is one of the

key long-term goals of Dell's 2020 "Legacy of Good" Plan. Since 2015, Dell has devoted

efforts to promoting supply chain water risk control, and plans to encourage

250 to 300 water-intensive suppliers to join its water risk mitigation project

by 2020. By adopting a water risk mitigation plan, Dell ensures that supply

chain water risks are effectively managed.

Since the launch of the project in

2015, more than 100 water-intensive suppliers have comprehensively identified

and assessed water risks linked to production processes, and taken subsequent measures

to control identified risks.

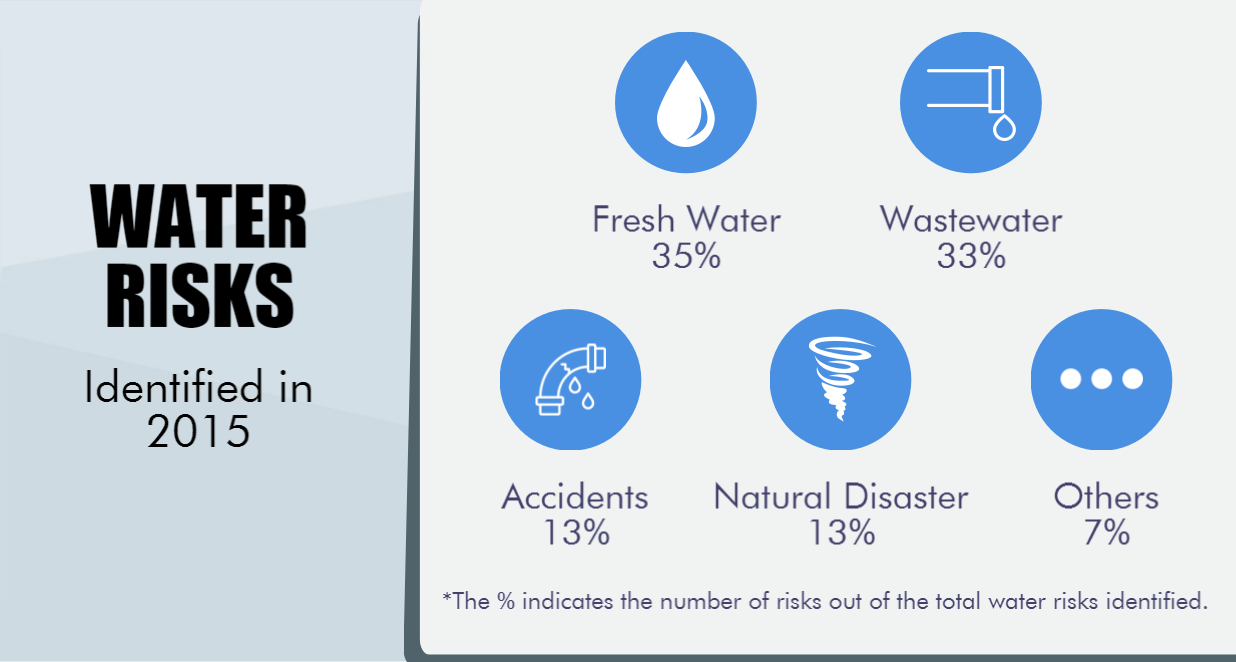

Among those participating suppliers,

50 suppliers that took part in Dell's water risk mitigation program in 2015

identified a total of 167 water risks. These risks include:

- Freshwater usage risks: Significant

water consumption during manufacturing, pollution of water sources, water wasted

during usage, etc.

- Wastewater discharge risks: Risk

of excessive wastewater discharge

- Water contamination accident

risks: Wastewater treatment system failure or damage to pipelines; outbreak of

fires; chemical leakages

- Natural disaster risks: Pollution

due to flooding, typhoons, drought, etc.

- Other water risks

To tackle the above risks, suppliers

proposed a total of 153 plans for water risk control. They adopted mitigation measures

such as recycling reclaimed water; collection, purification and recovery of

rainwater; refining water-saving equipment; analysis of water consumption

measurements; increasing the frequency of wastewater tests; checking for

pipeline leakages; and preparation and practicing of emergency action plans.

By 2016, a total of 1,029,821 tons of

water had been saved, whilst wastewater had been reduced by 3,074,267 tons.

Figure 1. Freshwater Consumption of Selected Dell

Suppliers

Figure 2 – Wastewater

Discharge of Selected Dell Suppliers

Several water-saving measures

implemented over the course of the project pose value and implications worth

studying:

Qunguang Photoelectric

Co., Ltd. (Suzhou) installed energy-saving faucets in its staff dormitory area.

It also replaced low-capacity flushing tanks on toilets with high-capacity

tanks, as well as canteen and bathroom faucets with delayed spray faucets. Implemented

measures resulted in a total of 33,288 tons of water saved in 2016.

After a water

risk identification assessment, Zhongda Electronics Co., Ltd. (Jiangsu) began collecting

water from their air conditioning and steam supply systems into a tank on the

rooftop of the building to be used for toilet flushing, condensation and other areas.

The tank installation reduced the amount of water in circulation in the

air-conditioning system as well as the amount of water used for domestic

purposes. These measures helped the enterprise save 8,575 tons of water in

2016.

In

addition, the factory is implementing a system for rainwater collection and reuse.

After filtering and purification, the collected water will be used for cleaning

sanitary ware, saving another 5,000 tons of water per year.

As part of the assessment for

supplier performance, Dell also requires all water-intensive suppliers

participating in the water risk mitigation project to fill in and publish their

pollutant release and transfer data via IPE's website. This disclosure includes

information on water consumption and pollutants in effluent.

Dell will continue actuating its

supply chain water risk mitigation plan to identify and assess water risks, and

continue to follow up on the effective implementation of water risk mitigation

plans in order to ensure that Dell's supply chain water risks are effectively

managed, thus fulfilling the brand's corporate social and environmental

responsibility.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)