Dell, the Natural

Resources Defense Council (NDRC) and the

Suzhou Institute of Energy Management jointly launched the Energy Management Capacity Building Project at the

beginning of 2016, targeting medium- and small-scale suppliers with relatively

weak energy management capabilities. The project divides energy management

capacity building into the following stages:

The first stage focuses on training in basic knowledge for energy

management and an analysis of gaps. It includes training the organization's

energy managers to understand the basic concepts and basic knowledge of energy

management; arranges an energy management, use and consumption on-site

diagnosis and gap analysis by energy experts; proposes energy management

improvement and energy-saving measures; and issues an energy audit report.

In the second stage, suppliers establish

an energy management system. This phase mainly includes a handbook guidance on energy

management systems; formulation, training and implementation of a management

system and implementation guidelines, guiding the formulation and

implementation of energy efficiency improvement measures, and training internal

auditors' capacity.

The third phase involves monitoring and

maintaining the effective implementation of the energy management system. This

phase is currently in progress.

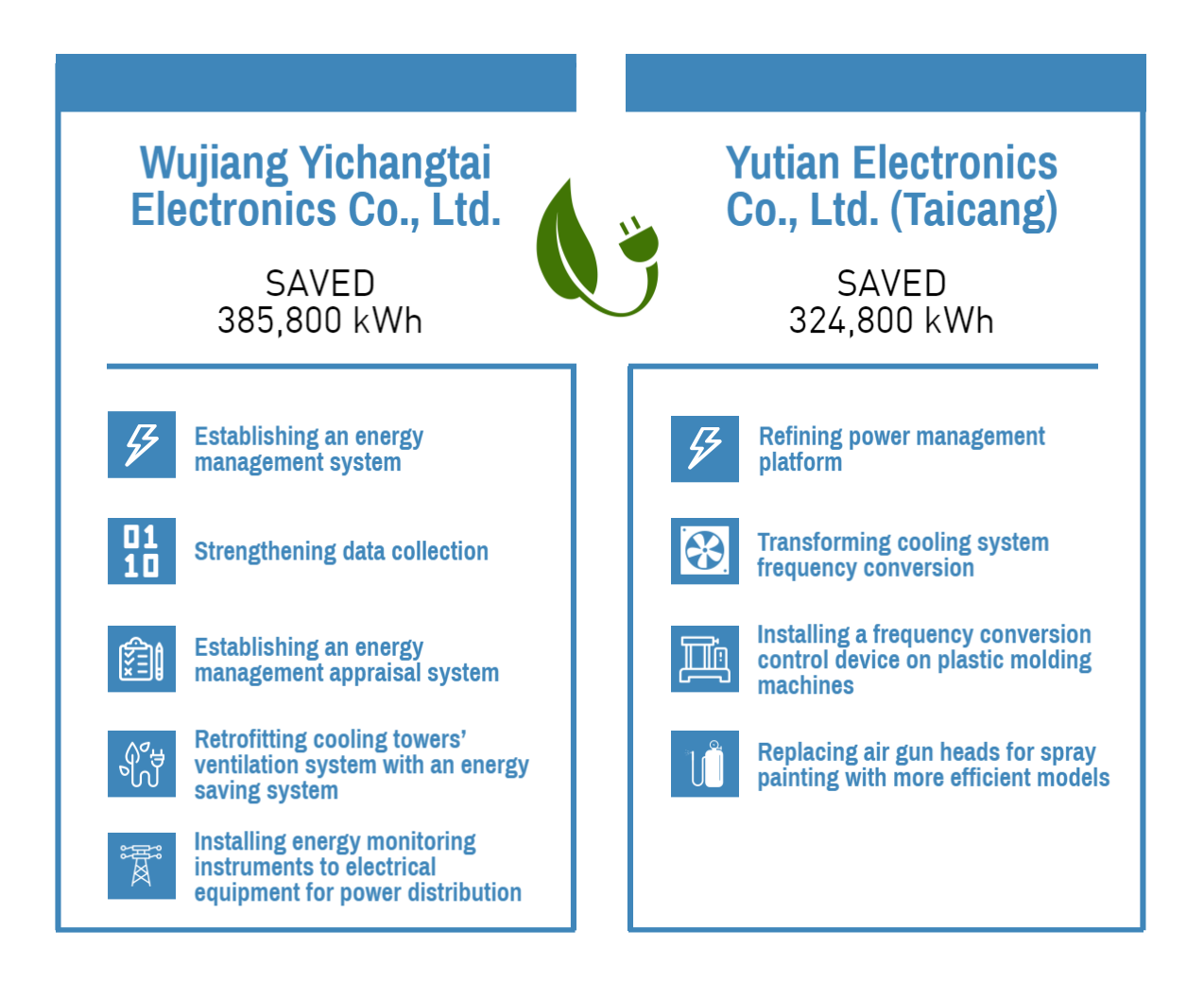

Two of Dell's participating

suppliers are seeing significant results from the initial implementation of the

energy management systems and energy-saving measures they adopted:

Yutian Electronics Co., Ltd.

(Taicang) transformed its cooling system frequency conversion, refined its power

management platform, installed a frequency conversion control device on its plastic

molding machines, replaced air gun heads for spray painting with more efficient

models, and adopted other energy-saving measures that may together save as much

as 324,800 kWh of electricity consumption.

Wujiang Yi Changtai Electronics Co.,

Ltd. also established an energy management system and energy management

appraisal system, strengthened data collection, adopted energy-saving measures

such as installing energy monitoring instruments to electrical equipment for

power distribution, and retrofitted cooling towers' ventilation system with an

energy-saving system. These improvements may together save as much as 385,800

kWh of electricity consumption.

Dell also requires suppliers to disclose energy consumption and greenhouse gas emissions data via CDP (click to view). By September 2017, Dell plans to motivate 95 suppliers in China to publish such information.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)