Brand CasesHuawei's Green Supply Chain Practices

Publication Date:2017-09-08

View:8177

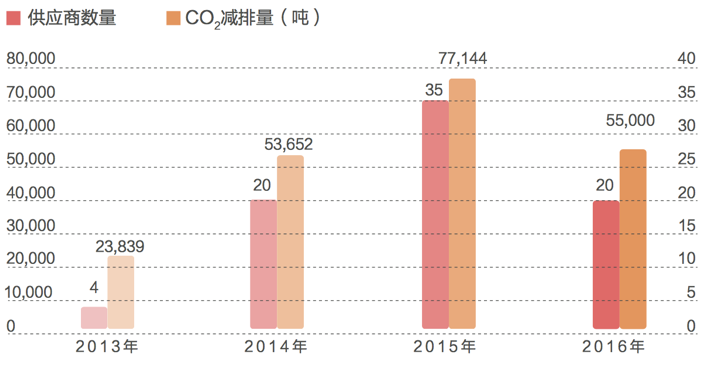

As Huawei’s global business expands, the

company has received concerns about its green supply chain from the government,

customers, third parties and other stakeholders. “Promoting green practices and

environmental protection” has become one

of Huawei’s sustainable development goals.

Huawei encourages its suppliers to set up

energy management organizations, carry out independent audits, identify energy

consumption and carbon emissions reduction opportunities, benchmark itself

against industry best practices and business cases, and develop and implement annual

energy conservation and emissions reduction plans. The company has selected suppliers

to test the acceptance of such measures.

In 2016, a total of 20 suppliers took part in energy conservation

and emissions reduction plans, reducing carbon dioxide emissions by a total of

55,000 tons that year.

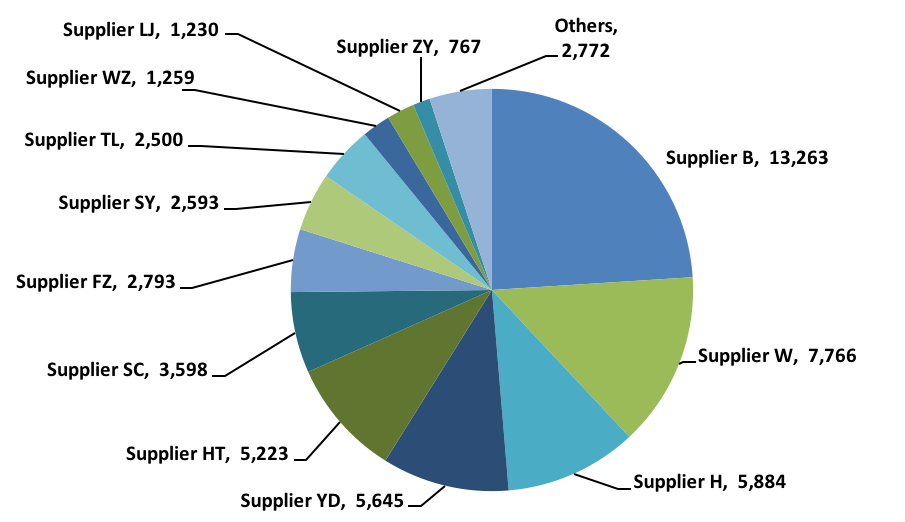

12 out of these 20 suppliers reduced their

carbon dioxide emissions by the following amounts:

Shennan Dianlu Co., Ltd. actively saved 3.6 million kWh of

electricity by installing infrared welding tunnel ovens and UVLED lamps, and by

replacing heating tubes with air heat pumps.

Dongguan Shengyi Electronics Co., Ltd. saved 2.6 million kWh of

electricity by using a central cooling system instead of its original drilling

machine oil cooler, upgrading the workshop’s technology (combined exhaust tower

network, increased frequency converter, etc.), transforming the boiler hot

water pipe network, increasing the circulating pump frequency control,

recovering waste heat from air compressors, and adopting other related green

measures.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)