Since Marks & Spencer launched its “Plan A”

in 2007, the brand has been committed to implementing a range of different

environmental projects.

At the beginning of the plan, M&S

selected its top-100 garment mills to participate in its "C-100 Energy

Conservation Project.” Nearly 80% of these suppliers are located in China. Working

with technical and industry experts, M&S found that the plants could reduce

energy use at least 10% by improving three key areas in the factories:

lighting, separation measures and temperature control.

Since the performance of the plants was

better than expected, in 2011, M&S launched an advanced “ECO Factory

Program” to more comprehensively promote improvement in different areas at the

plants, focusing on the four areas of energy efficiency, renewable energy,

water and waste management. 34 factories have achieved at least 20% energy

savings from the program.

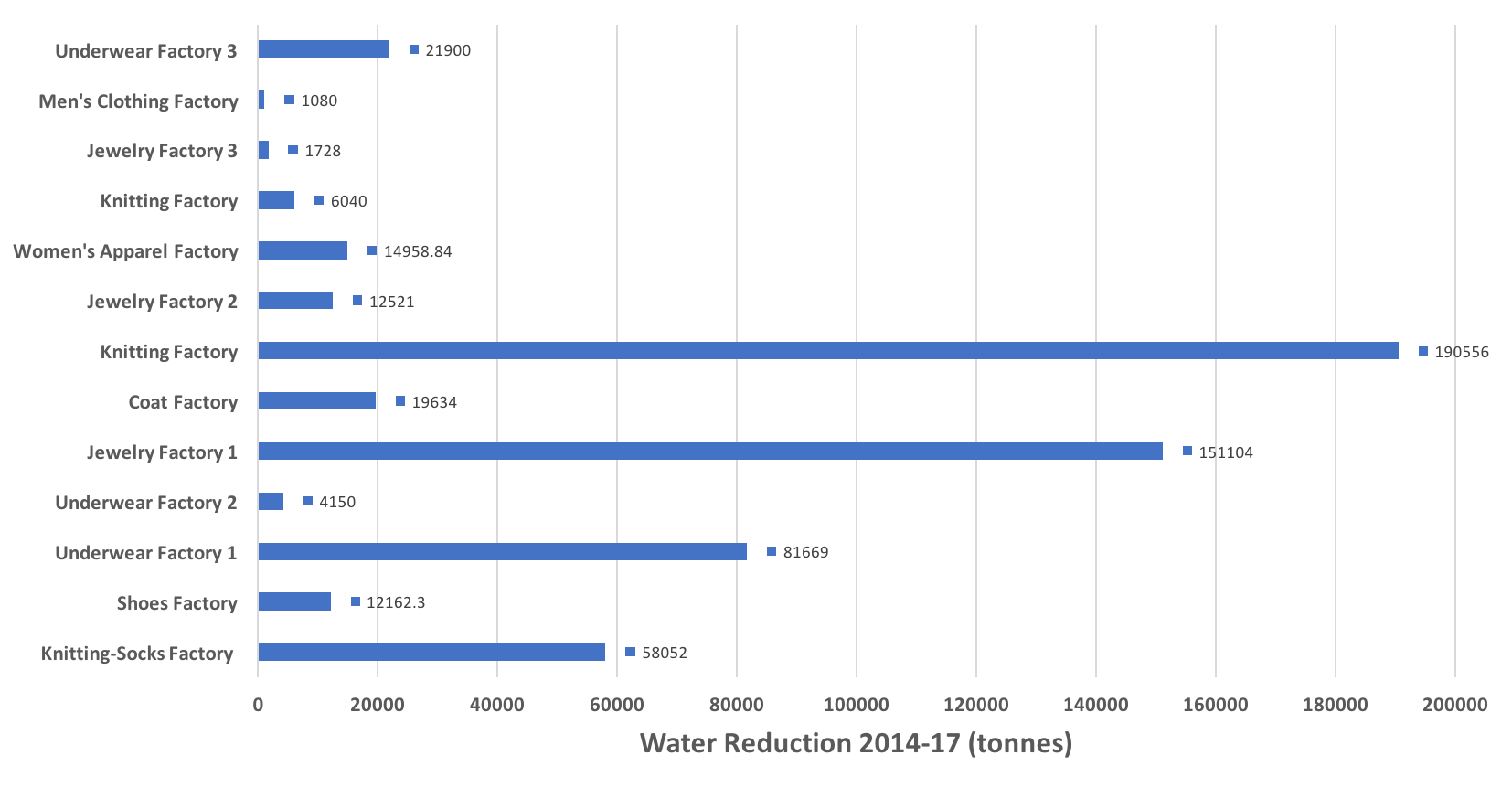

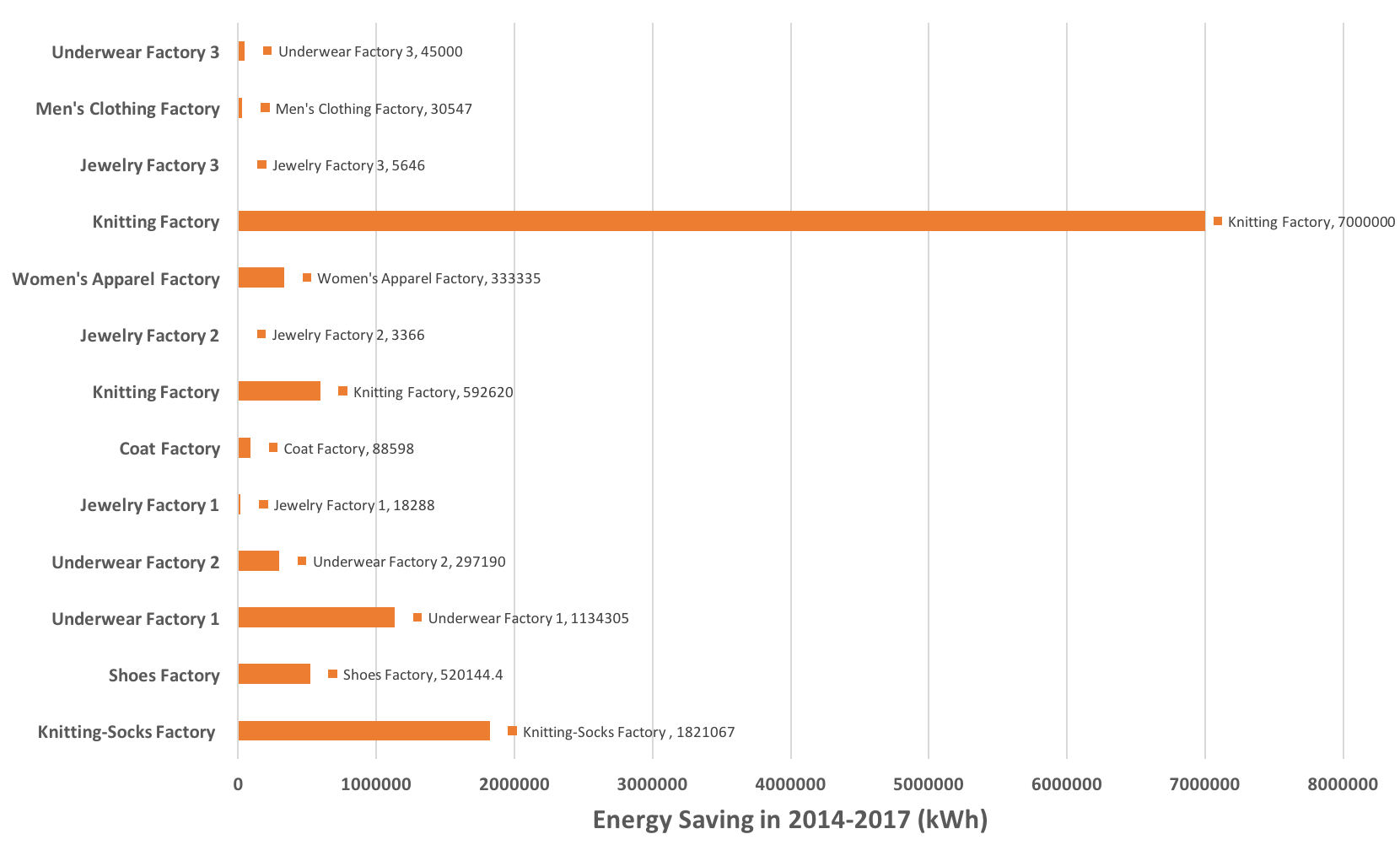

From 2014 through 2017, there were 13

factories in total awarded the “ECO factory” label, ultimately saving 575,555

tons of water and 11,890,106 kWh of electricity annually.

In July 2017, Marks & Spencer successfully

pushed an intimates apparel factory in Guangdong Province become an “ECO

Factory” through three years of training and engagements, starting with the management

team and going all the way down to the front line of workers.

This factory successfully reduced its electricity

consumption by approximately 45,000 kWh and reduced its water consumption by

around 21,900 tons, totaling 27% energy reduction at the factory. The factory exhibited

a number of achievements across different production areas, including the use

of energy-saving motors, LED lighting systems, high-performance air compressors,

a green air conditioning system, a steam recycle system, and strengthening the

machinery maintenance inside the plant. These actions all helped to improve the

factory budget by significantly reducing production and operating costs. As a

result, the plant is very eager to move forward in this direction by setting up

energy-saving targets for the next five years, including a further reduction of

10% in electricity consumption, 10% of water consumption, 10% of production

waste and 50% of kitchen waste.

Last year, over 40% of all products M&S

sold were made in M&S-approved eco- factories. These are factories that

have demonstrated significant savings in their energy, water and waste

footprints.In the future, Marks & Spencer will

continue to drive more plants to join its efforts to develop a green supply

chain.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)