Brand CasesEsquel Group Factories Adopt Sustainable Practices

Publication Date:2017-09-13

View:4957

Esquel Group conducts

a series of initiatives to effectively monitor energy and climate change data

and pollutant emissions and transfer (PRTR) data in its spinning, weaving,

packaging, water treatment, sewage treatment and thermal power plants located

in mainland China. Furthermore, the company has taken energy-saving,

consumption-cutting and emissions-reducing measures to meet its annual targets

for energy savings and emissions reduction in its entire spinning and weaving

supply chain.

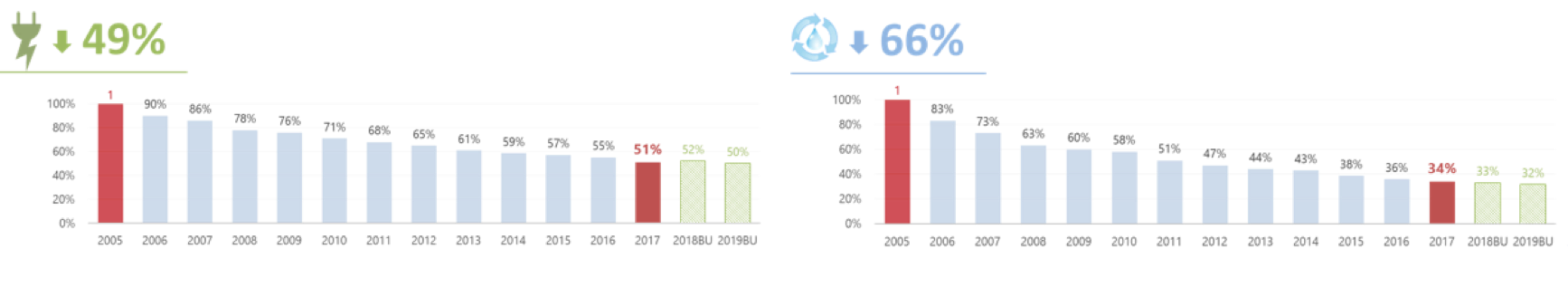

Esquel Group’s energy and water consumption reduction targets since 2005 are as follows:

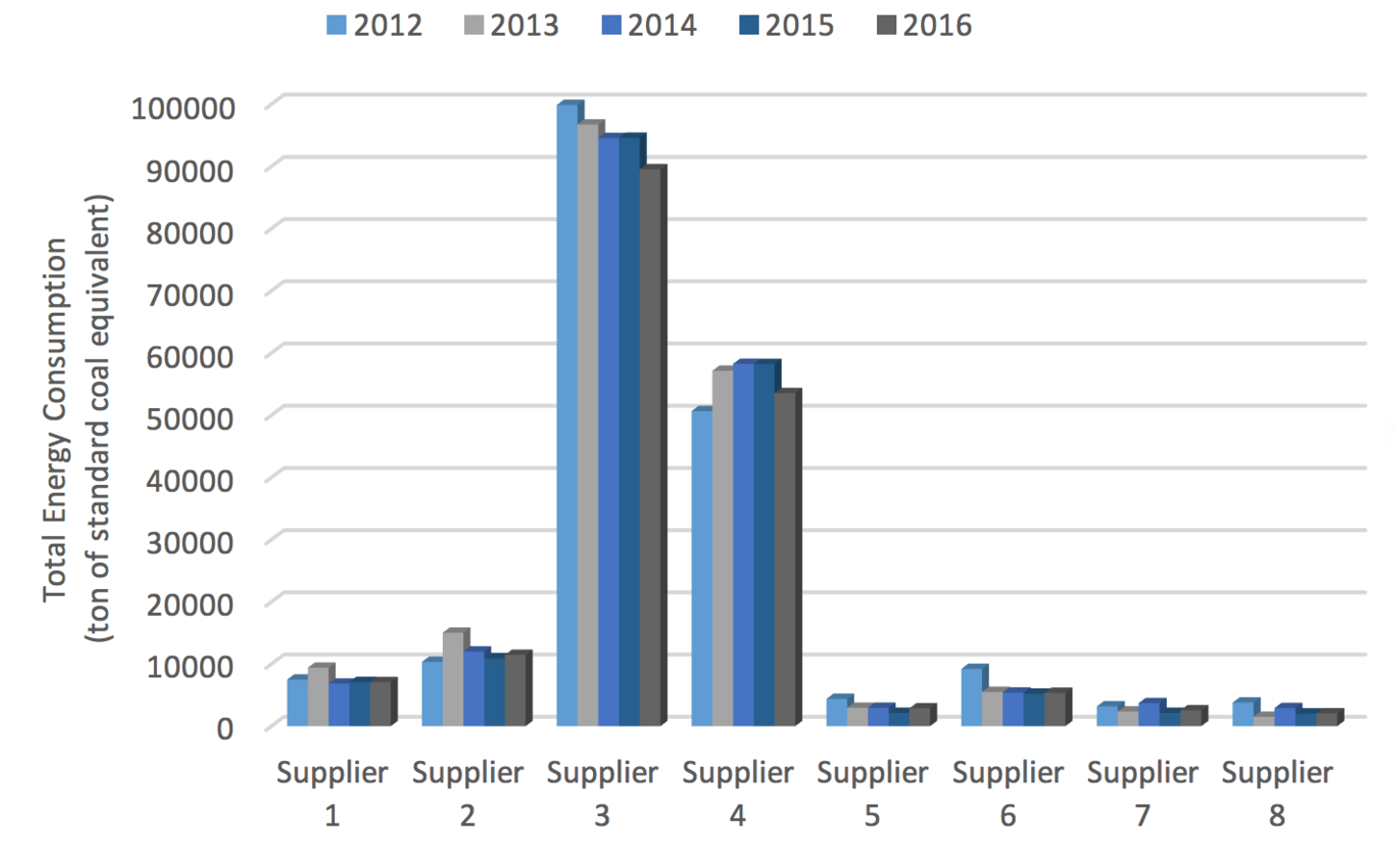

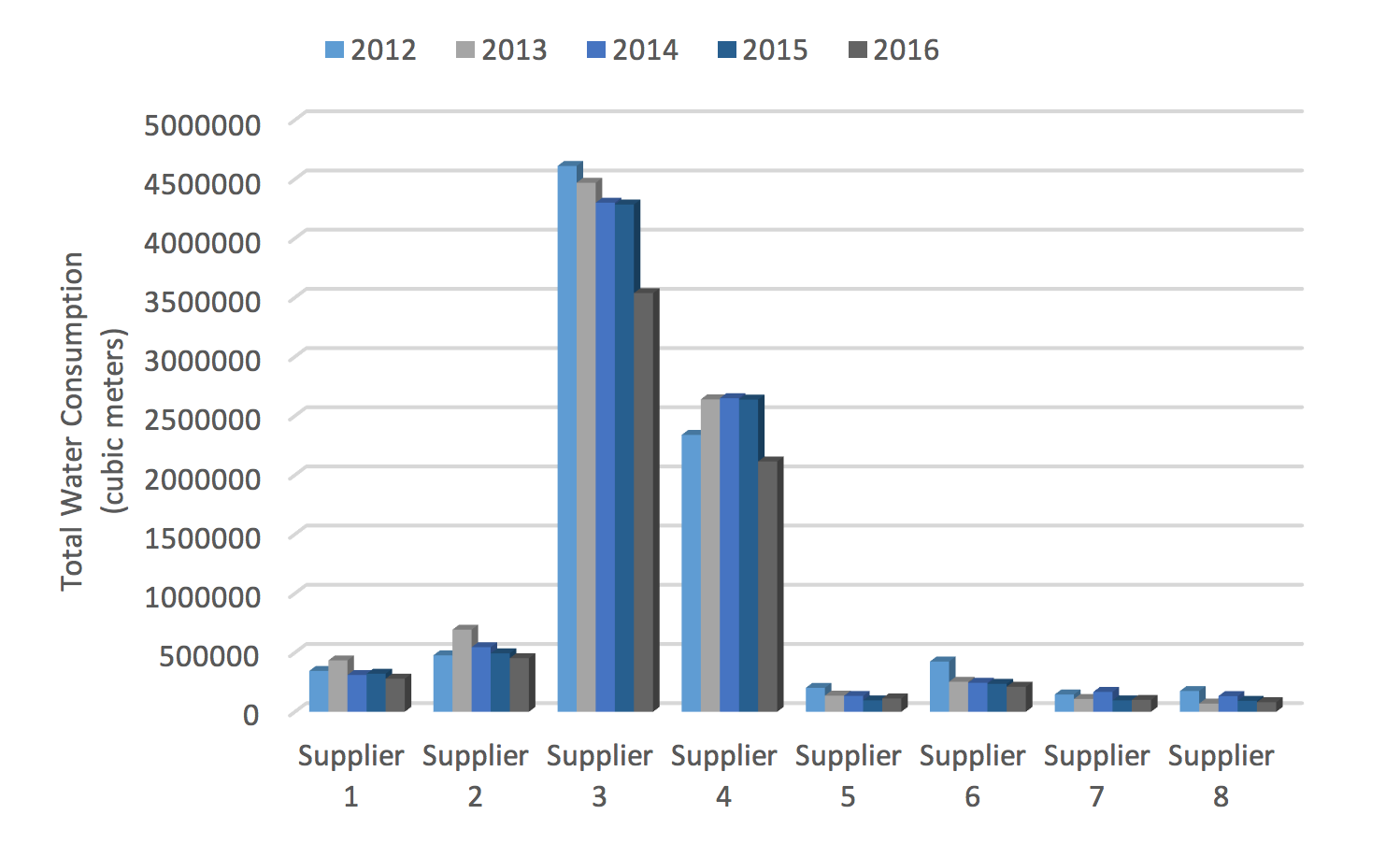

The Guangdong-based Esquel Group has determined energy-saving

targets for factories with air emissions and wastewater discharge as a key

focus of its green supply chain control efforts. These targets are based on

each factory’s production specificities and emissions requirements and include

targets for coal consumption, diesel consumption, electricity purchase, natural

gas consumption, total water intake as well as total energy consumption. Energy

and water consumption by eight subsidiaries of Esquel from 2012 through 2016

was as follows:

Among these

suppliers, the biggest consumer of water and energy is Supplier 3, a fabric

manufacturer. Esquel promotes the implementation of a series of objectives

based on the specific characteristics of the factory’s production processes.

These include eliminating sizing agents to avoid the de-sizing process,

relieving the -1/-E pre-shrink process, high energy-efficiency projects,

updating the features of dyeing machines, and realizing other year-long

water-saving and energy-saving targets.

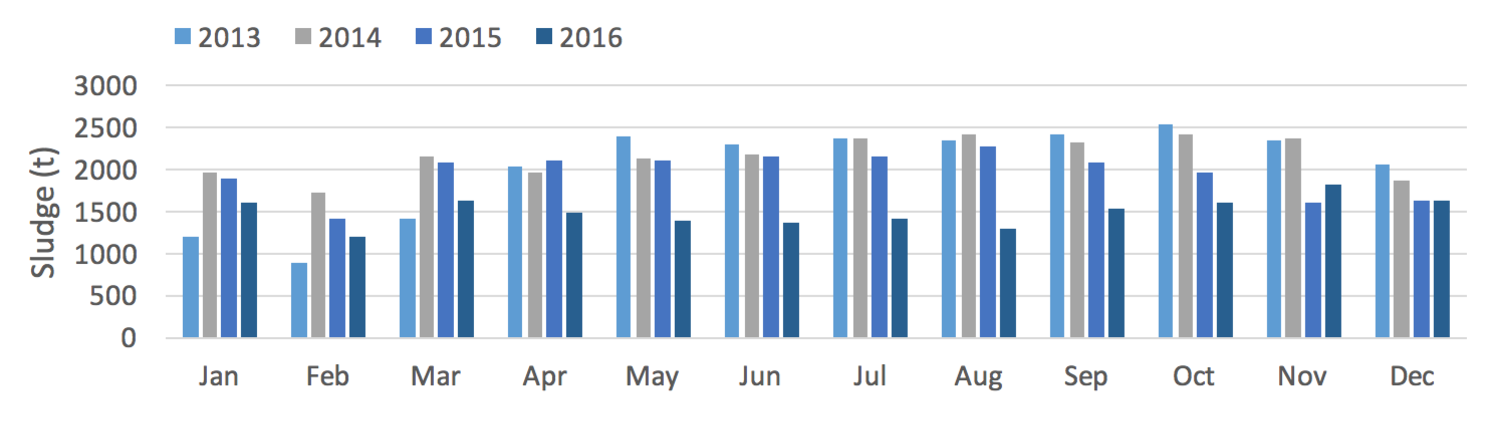

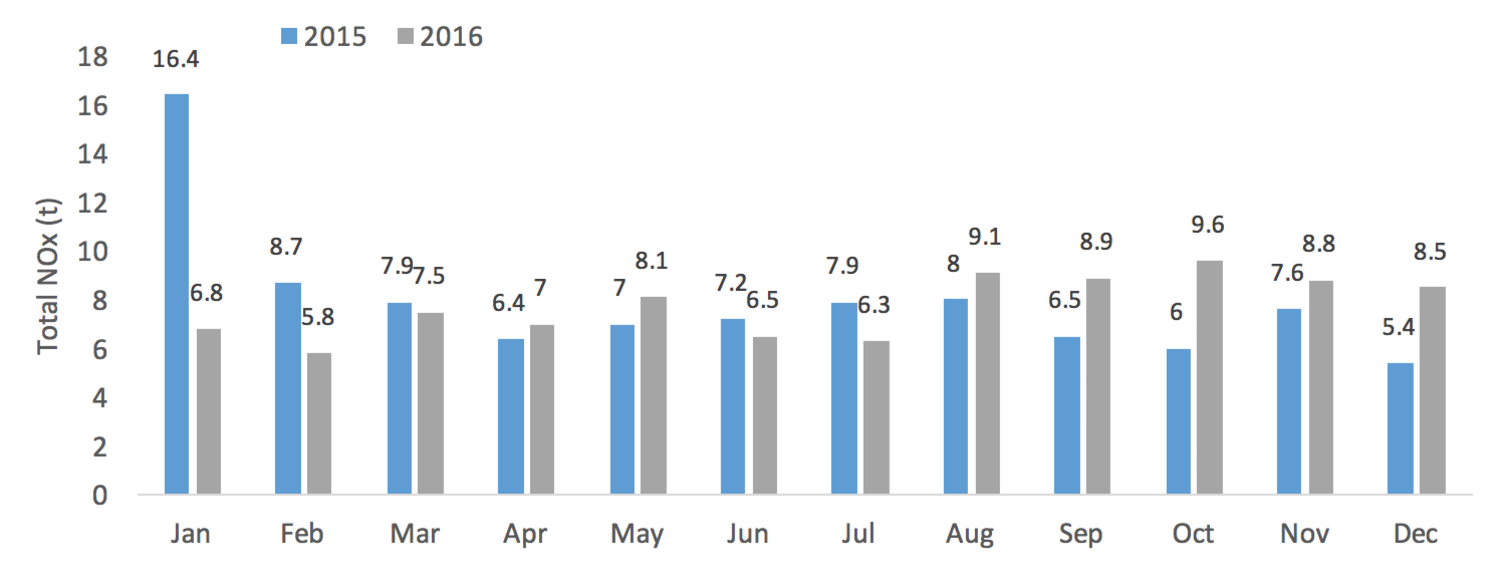

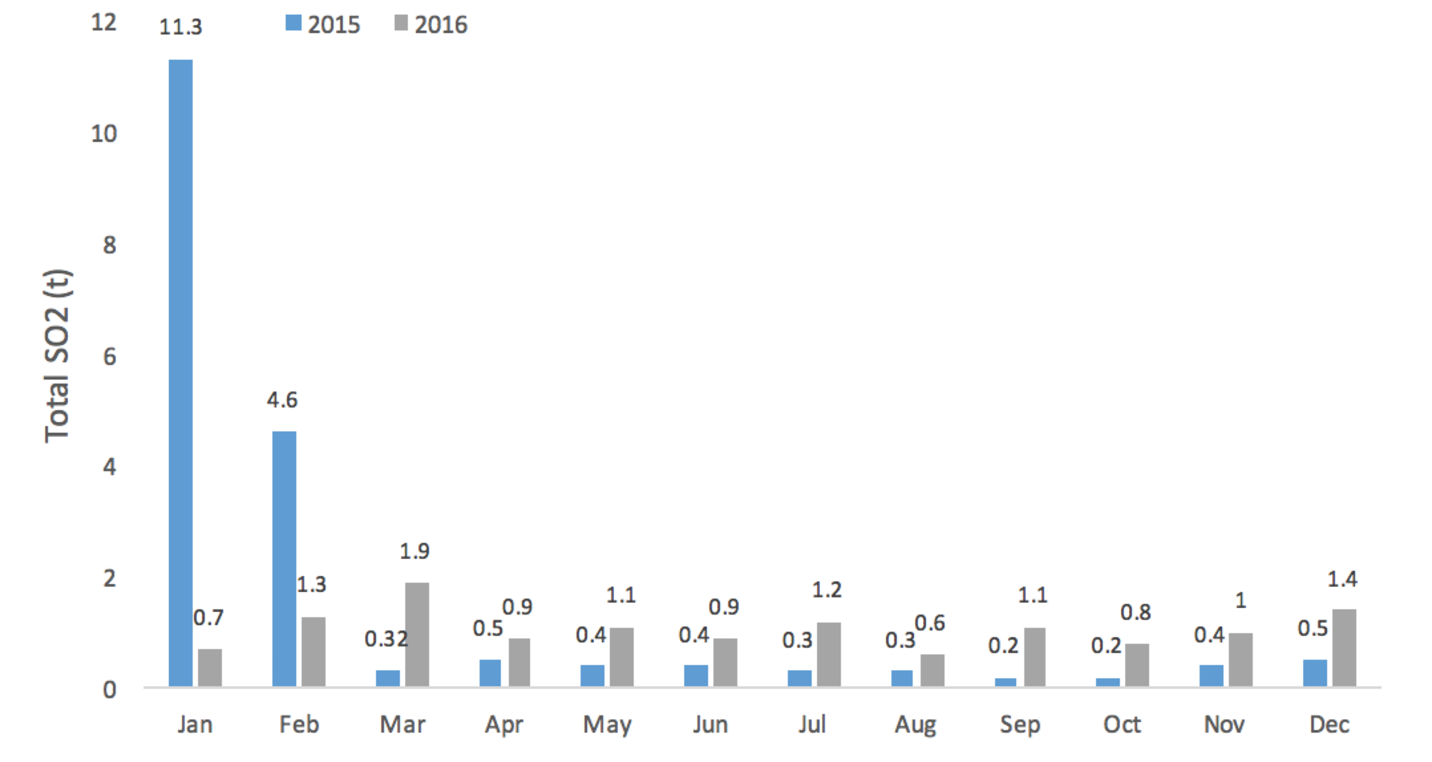

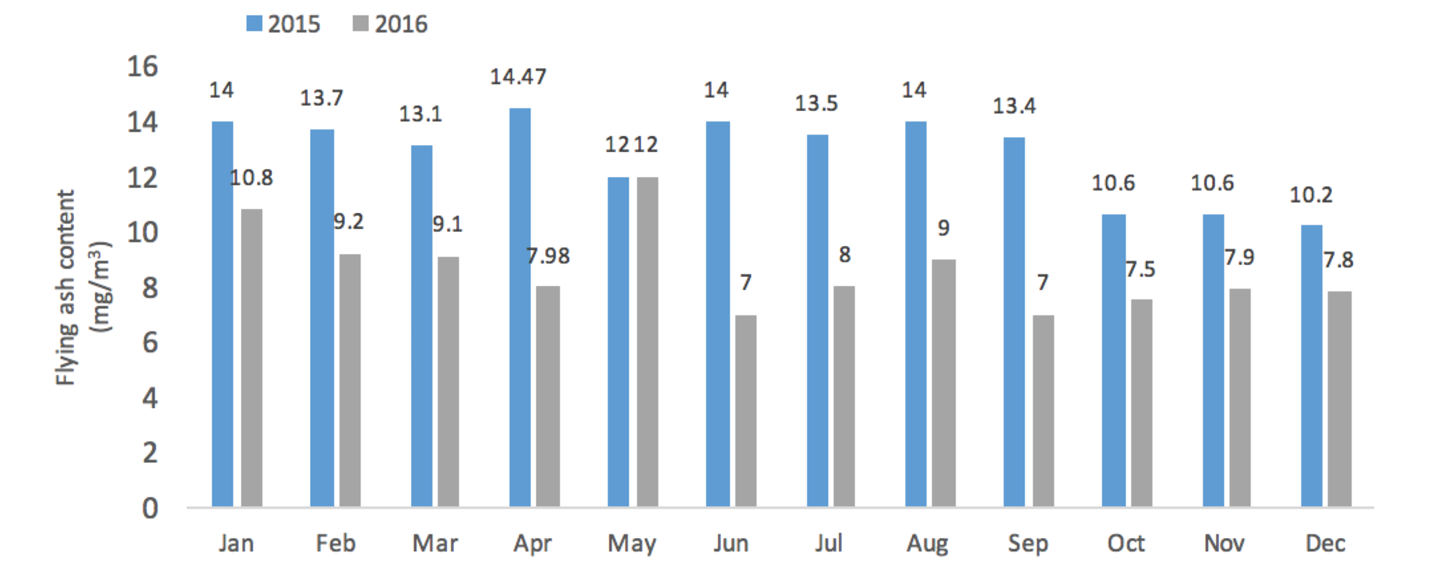

To focus on the company's sewage treatment center and

thermal power plants, Esquel Group set up multiple targets concerning the

amount of sludge generated by the sewage treatment center, power plant flue gas

emissions, thermal power plant boiler SOx emissions, and flue gas flying ash

particles content as well as its comprehensive utilization. Furthermore, the

Group monitors the impact of its supply chain on the environment and strives to

minimize this impact.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)