Foxconn, an

international technology manufacturing company, has been committed to

environmental protection by promoting the transformation of upstream suppliers into

a green supply chain and achieving remarkable results. One of Foxconn's leading

upstream suppliers of electronic components, Manufacturer A, attaches great importance to the long-term

value of green innovation in light of joint efforts between Foxconn and Manufacturer A.

The environmental

strategy undertaken by Manufacturer A and the effectiveness of various indicators are detailed as follows:

Environmental

Strategy

Based on the

strategy of "two pillars: green production + good management", Manufacturer A develops water and energy consumption reduction indicators for each

production unit and tracks them on a quarterly basis. To manage these two

pillars is to check and manage energy savings, water savings, emissions and discharge

at three points: the beginning of the manufacture process, the production

process and the end of the production line, in every factory. The scope covers

5 categories, including 5S, energy savings, water savings, exhaust emissions

and waste. Through the implementation of the above management strategies, a

solid foundation will be laid for the promotion and demonstration of

environmental sustainability.

Environmental Management Achievements

Ø Energy

conservation and emissions reduction

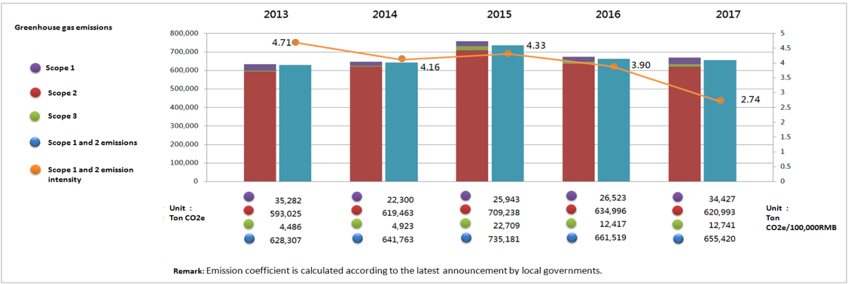

In 2017, the

greenhouse gas emissions total of Scope 1 and Scope 2 of Manufacturer A’s main production

base was 655,420 tons of CO2e. This was achieved by implementing intelligent

improvements to the ice water machines and energy-saving improvements to the

vacuum press, as well as adding nitrogen energy-saving equipment to the reflow oven,

waste heat recovery to the process oven and other energy-saving technologies

and management practices. In 2017, the emissions of Scope 1 and Scope 2

decreased by 0.92% compared to 2016.

Figure 1

Ø Water use reduction

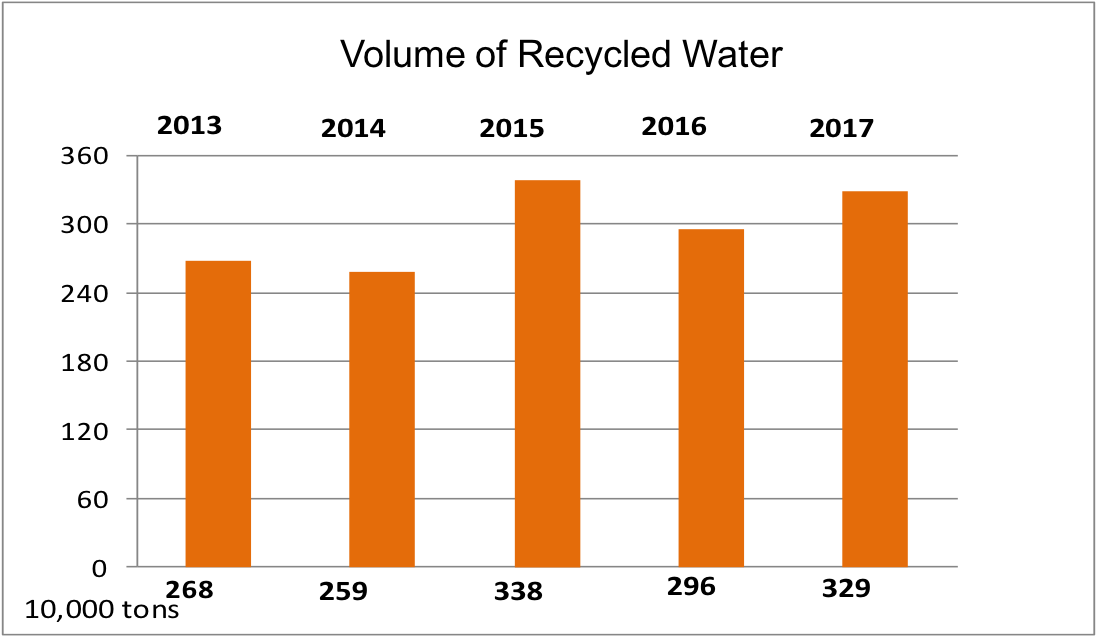

Manufacturer A also adopted

the strategy of "recycling, water conservation, diversion of rain and

sewage" to minimize the risk of environmental pollution caused by external

drainage. For example, over the years, manufacturer A has been promoting a

number of water-recycling and water-saving projects, including steam condensate

recovery, RO concentrated water reuse, rainwater recovery, and automatic

spillover control at the production level, among others. In 2017, the use of recycled

water exceeded 3 million tons. (Figure 2)

Figure 2

Ø Exhaust

emissions reduction

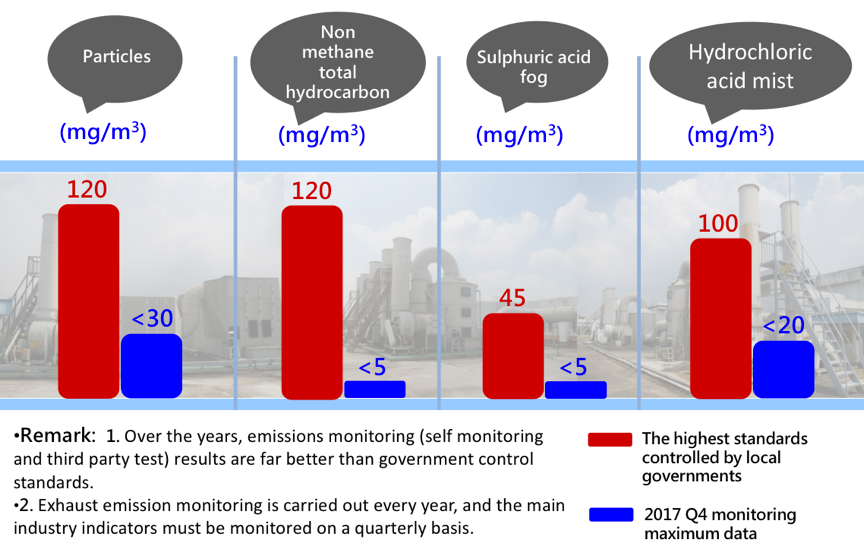

Manufacturer

A improves and guarantees the good air quality of the surrounding area by

installing air pollution prevention and control equipment such as packed

scrubbers, bag dust collectors, and activated carbon absorption towers, as well

as conducting daily spot inspections and the removal of abnormalities in the

exhaust emissions systems.

At the same

time, every year, Manufacturer A independently and regularly invites external professional

organizations to carry out testing, and continuously track the monitoring data

of various pollutants to ensure that all emissions indicators are up to

standard, or even better than the domestic standards.

Figure 3

Ø Waste

management

The waste management strategy of Manufacturer A is: “harmlessness,

reductions and resourcefulness.” To this end, all sites have set up special

units for waste disposal and promoted the project of "waste management

throughout the whole process" in each factory. Each factory has appointed professional

supervisors and individuals to jointly implement waste classification management

and formulate a sound waste management and transportation process.

Manufacturer A also promotes a variety of hazardous

waste reduction technologies, including the drying of membrane residue, sludge

and filter elements, and the autonomous recovery of precious metals. The production density of hazardous waste per unit revenue in 2017 is 15.9% lower than it

was in 2016. Over the past year, the proportion of waste resource recovery reached

more than 90%.

Figure 4

Environmental management achievements

Manufacturer A achieved the government and internal

supervision goals for environmental protection and energy conservation from the

two directions of "energy saving with reduced consumption; pollution

reduction with increased efficiency". Fig. 5 shows the comparison of Manufacturer A’s green

performance data between 2017 and 2013.

Figure 5

In the future, Foxconn will continue to

promote supply chain environmental protection. In order to solve the

current and future potential environmental risks, Foxconn aims to pay more attention

to coordinating the harmony between humankind and nature, and ensuring the

sustainable development of the economy and society. Foxconn will work together

with a vast number of suppliers to realize the vision of coexistence and

harmony between cutting-edge technology and the ecological environment.

(The above content is provided by the

brand, and the authenticity of the data is the responsibility of the brand).