Brand CasesApple Supplier Zero Waste Program -- 100% Committed to Zero Waste

Publication Date:2017-08-23

View:8556

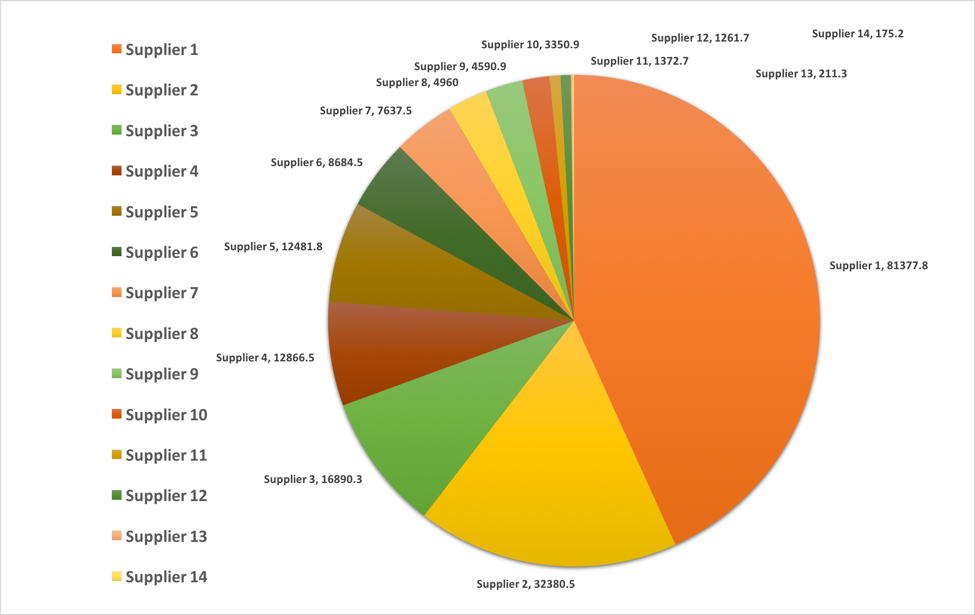

In 2016, Apple

increased efforts to reduce and ultimately eliminate manufacturing waste sent

to landfills by expanding its UL Zero Waste to Landfill validation program to all final assembly

sites in China. The program is the first comprehensive standard for waste

conversion and calculation, with a focus on waste stream management compliance,

inspection and auditing.

The

total volume of waste diverted from landfills more than doubled year-on-year,

from nearly 74,000 metric tons in 2015 to more than 200,000 metric tons in

2016. The number of suppliers certified globally via third-party audit as zero

waste has also increased from one factory in 2015 to 15 suppliers in 2016. The reduction

performance of 14 suppliers in China in 2016 is shown below (unit of measure:

tons):

One

of the participants is Tech-Com in Shanghai. Apple discovered that more than 20

percent of the waste produced by Tech-Com was being incinerated or going to

landfills. Apple partnered with the supplier and their local recycling facility

to develop a better process for separating and recycling waste. As a result,

Tech-Com is now able to recycle all of their manufacturing waste. Tech-Com also

developed a new process for managing food waste, allowing the supplier to send

it to a local composter instead of a landfill. Tech-Com then used what they had

learned to develop a process for their own suppliers that helps them collect

and reuse packaging material. Since the program started, Tech-Com has diverted

more than 10,000 metric tons of waste from landfills.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)