At Nike, our sustainability programs are driven by a desire to help protect the planet and create a better future for sport. The Nike Water Program plays a key role in this strategy.

When we at freshwater use, we take a “black box approach”to water conservation. That is, we look at freshwater use across the entire facility. We do not simply focus on dyeing or other manufacturing processes. We treat each facility as a black box with freshwater entering and sellable material leaving the facility. All facilities have washrooms with toilets and sinks. A facility may also have dormitories, irrigation, kitchens, and other water-intensive manufacturing processes such as water-jet weaving looms that normally take freshwater from the local watershed. We include this freshwater use in our liters/kg production metric because, in the end, we’re concerned about the overall impact each facility has on the local watershed’s freshwater resources.This approach makes it more challenging to achieve our freshwater reduction targets, but we believe it’s the more responsible, holistic approach to protect the environment.

For almost six years, Nike has championed wastewater recycling as one of the main strategies to reduce our freshwater footprint and to minimize the amount of wastewater discharged into the environment. This strategy is paying off. By the end of Nike’s 2019 fiscal year (FY19)[i], we reduced our global freshwater use by 25.4 percent vs. our 2020 target of a 20 percent reduction (on a liters/kg basis) from a FY16 baseline. In 2015, only one of Nike’s five key suppliers in China had plans to recycle dyehouse wastewater. Now, four have installed wastewater recycling, and the fifth is studying its feasibility. Through wastewater recycling, process optimization, and installing more water-efficient manufacturing equipment, those five Chinese facilities helped us hit our goal, and avoided using a cumulative 12.6 billion liters of freshwater between FY17 and FY19. Of the 12.6 billion liters saved, 4.3 billion liters would have been used to produce Nike textiles, while the remaining 8.3 billion liters saved benefited other brands that share our supply chain. For reference, 12.6 billion liters of water would sustain approximately 100,000 Guangzhou households for an entire year.[ii]

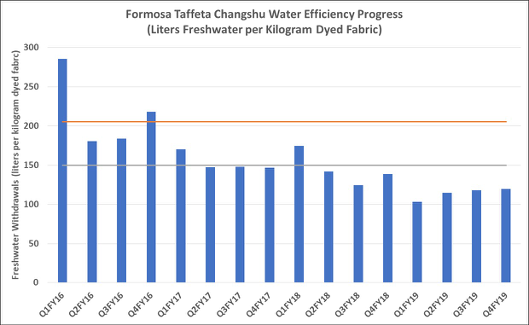

One of those five Chinese facilities, Formosa Taffeta in Changshu, China, embraced water sustainability, adopted the Nike Water Minimum Program, and committed themselves to wastewater treatment and recycling. In 2014, Formosa Taffeta’s Changshu facility was featured in the Green Choice Alliance Phase 4 Textile Industry Report, “No Excuses: Taking Full Responsibility for Pollution from Manufacturing”. At that time the facility, per their agreement with the industrial park wastewater treatment facility, was discharging a chemical oxygen demand (COD)[iii]concentration close to 1000 ppm. Since then, Formosa constructed a biological wastewater treatment plant and a wastewater recycling facility complete with ion exchange, ultrafiltration, and reverse osmosis treatment technologies.

By the end of Nike’s FY19, Formosa’s Changshu facility reduced their freshwater use (on a liters per kg basis) by nearly half. In actual terms between FY17 and FY19, they avoided using 425 million liters of freshwater. That’s 425 million liters of water that was made available to surrounding communities, the ecosystem, farmers, and other industrial users.What makes Formosa’s accomplishment even more remarkable is that Formosa Changshu is also fully compliant to the Zero Discharge of Hazardous Chemicals (ZDHC) Wastewater Guideline[iv], a dual win. They were discharging treated wastewater with a COD concentration of 58 ppm, almost a third of the legal limit (200 ppm), and a 94 percent decrease from when the Green Choice Alliance published their report in 2014. Beyond the walls of the factory, Formosa’s efforts are a positive step for nearby Taihu and the surrounding water systems, which for years have been plagued by industrial pollution.

We are only at the start of our journey. We know that 90 percent freshwater reduction is achievable with commercially available equipment and proper training of those responsible for operating the equipment to manage, treat, and recycle wastewater. We will continue to champion the Nike Water Minimum Program, wastewater recycling, and the technical training necessary for all suppliers to achieve their dual win of significant freshwater reductions and regular compliance to the ZDHC Wastewater Guideline. At Nike, there is no finish line.

If any divergences arise between the English and the Chinese versions of this report, please refer to theEnglish version.

[i]Nike’s fiscal year runs from June 1 to May 31. Therefore, fiscal 2019 runs from June 1, 2018 to May 31, 2019.

[ii]Z. Zhang, J. Liu, B. Cai, Y. Shan, H. Zheng, X. Li, X. Li, and D. Guan “City-level water withdrawal in China: Accounting methodology and applications”, Journal of Industrial Ecology, https://doi.org/10.1111/jiec.12999, March 9, 2020.

[iii]Chemical Oxygen Demand or COD is a measurement of the oxygen required to oxidize soluble and particulate organic matter in water.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand)