In response to the Paris Agreement on the 15° C climate route, countries around the world have taken the initiative to formulate a carbon neutral schedule and put it into action. Sustainable development of enterprises has become a hot topic today, and leading international brands have formulated a carbon neutral schedule to effectively implement ESG. Foxconn Group actively responds to the CA100+ climate action and commits itself and the value chain to achieve carbon neutrality by 2050, and suppliers, as an important part of the value chain, must take immediate climate action. Based on this, Foxconn supplier's carbon neutrality policies and requirements are as follows:

1. Suppliers must commit to achieve carbon neutrality by 2050, and formulate scientific carbon reduction targets, take active and effective measures to continuously promote the achievement of the target. If the end customer has more stringent requirements, customer requirements shall prevail.

2. Suppliers must disclose carbon emission data and carbon reduction results verified by a third party in Foxconn Greenhouse Gas management digital platform every year (https://ghg.foxconn.com/GP_GHG/login.jsp)

3. Suppliers should implement energy saving and carbon reduction projects (such as building photovoltaic solar energy, using renewable energy and Energy storage project, etc.) to reduce carbon emissions, and ultimately achieve carbon neutrality. Foxconn conducts performance assessment on energy conservation and carbon reduction of suppliers, and the assessment results serve as the basis for the increase and decrease of suppliers' orders and the selection and elimination of inferior suppliers.

Foxconn formulated a scientific carbon reduction goal and disclosed it on its official website. In order to promote suppliers to achieve Foxconn's scope 3 carbon reduction goal, the group's central procurement department selected 10 out of 75 key electronic suppliers for energy-saving project. Through energy-saving of major energy consuming equipment, suppliers have improved energy utilization efficiency, thereby reducing carbon emissions generated by outsourcing power, so as to meet the requirement of Foxconn scope 3 target to reduce carbon by 4.2% annually. The emission reduction case of a Foxconn supplier illustrates how to work with partners to reduce carbon emissions in the supply chain.

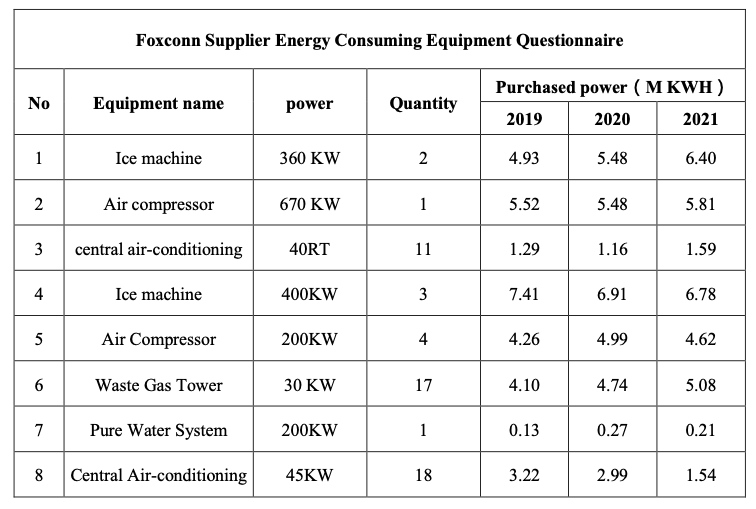

A Foxconn supplier mainly provides high-end customers with printed circuit board products such as communications, computers and servers, automotive electronics, etc. Through the statistics of Foxconn supplier carbon emission questionnaire, the list of main energy consuming equipment of the supplier is analyzed, and according to its operational performance parameters, the on-site diagnosis plan is formulated, and the operation of energy consuming equipment is investigated on the spot.

Table 1: Questionnaire On Energy Consuming Equipment of Suppliers

In order to tailor-made energy-saving improvement plans for suppliers, to conduct on-site diagnosis of peripheral equipment of the factory, because ice water main engine, air compressor and cabinet air conditioner are all high energy consuming equipment. At the same time, professional diagnosis should be carried out regularly to evaluate the operating efficiency of the equipment.

Figure 1: Technical Exchange between Foxconn and Supplier

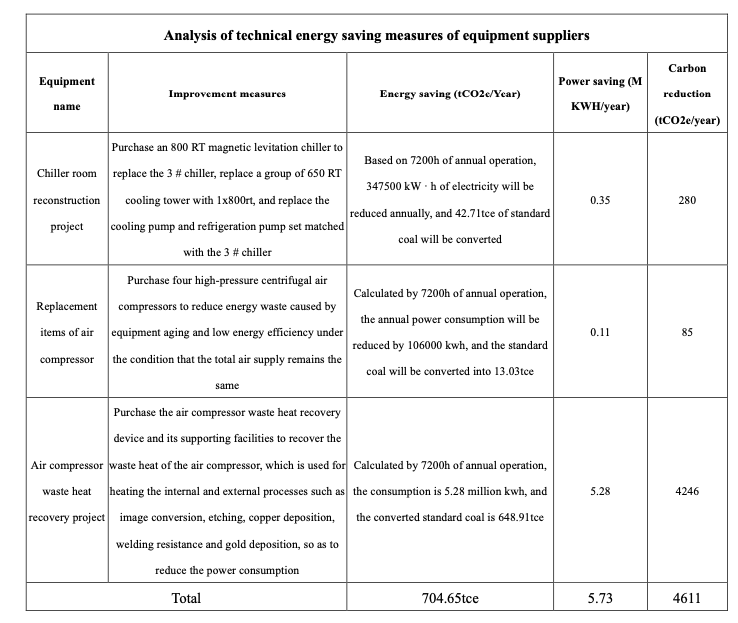

Through on-site diagnosis and communication, it is recommended that suppliers carry out energy-saving plan according to Foxconn's technical energy-saving measures, improve energy efficiency, and achieve the goal of reducing carbon by 4611 tons per year.

Table 2: Energy Saving Improvement Projects of Supplier

The supplier owns its own plant and has a large effective roof area, which is suitable for building roof photovoltaic solar energy projects. Therefore, the supplier also decided to start the roof photovoltaic solar energy project according to national policies and Foxconn's requirements after a full evaluation by a third party. The installed capacity of the project is 3MW, which can generate 4.5 million kWH of power and directly reduce 3618 tons of carbon emissions based on 1500h of light every year.

Figure 2: Schematic diagram of photovoltaic solar energy

Photovoltaic solar energy project is a supporting energy storage project, which is also the development trend of renewable energy in the future. After benefit evaluation, the supplier decided to start the construction of energy storage project. The annual discharge of the battery energy storage project is 4.75 million degrees, which can make a profit of 341,000 Yuan through peak valley power consumption regulation, and save a total of 25.81 million Yuan in 25 years. Suppliers can obtain huge economic benefits while obtaining environmental benefits. It is an important project for enterprises to lay out the future.

Figure 3: Schematic diagram of energy storage project

Foxconn suppliers can reduce 8,229 tons of carbon per year through energy-saving and the use of renewable energy. The annual carbon emissions of Foxconn products produced by Foxconn are 16000 tons, which can fully meet Foxconn's requirement that suppliers reduce carbon by 4.2% per year. The successful energy-saving and renewable energy use cases implemented by suppliers will form an excellent case base and be promoted to more suppliers, so that more suppliers can meet Foxconn's carbon reduction target.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)