Levi Strauss & Co., a globally recognized apparel brand and sustainability pioneer, has been actively advocating and committing to the sustainable development of the global green supply chain.

At the group level, we have remained dedicated to pursuing the following objectives in our global supply chain since the publication of our 2025 Climate and Water Action Strategy in 2018 and 2019, respectively:

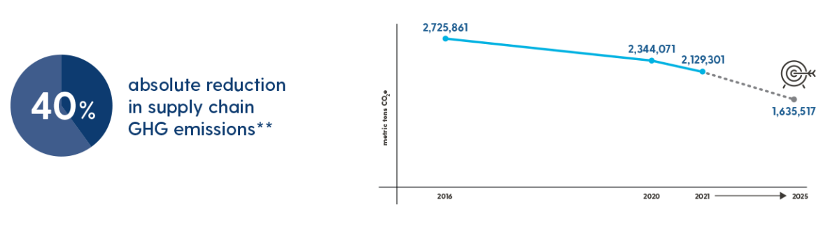

• 40% reduction in GHG emissions with 2016 as the base year (Scope 3, Category 1 - Procurement of goods and services).

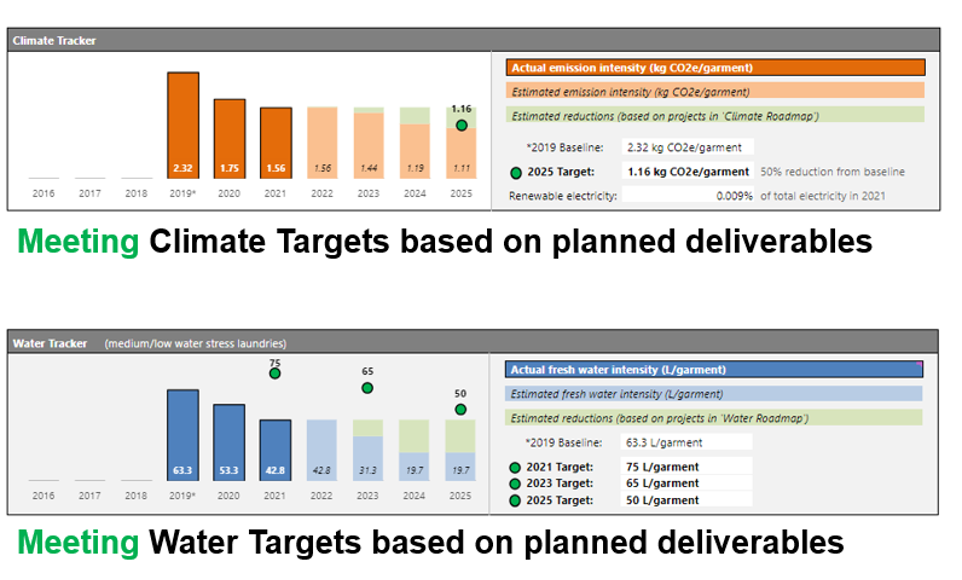

• 50% reduction in water usage for production in areas of high-water scarcity, with 2018 as the base year.

• In 2021, we further set a target to archive net-zero GHG emissions no later than 2050.

Progress towards the achievement of the Goals include:

• Reduction in GHG emissions by 22% in FY 2021 using 2016 as the base year (Scope 3 Category 1 - Procurement of Goods and Services).

• 22% reduction in water usage for production in high water scarcity areas in FY2020, using 2018 as the base year.

• In FY2021, the amount of water reused for the production of the Levi Strauss & Co. reached 3 billion liters.

(More detailed information can be found in the LS&Co.: Sustainability Resources - Levi Strauss & Co : Levi Strauss & Co)

As a globally recognized apparel brand, we understand that achieving strategic goals requires collaboration and engagement with various stakeholders. Over the past decade, we have established a fruitful partnership with the Institute of Public and Environmental Affairs (IPE) in China, which has been a catalyst for our mutual growth and expansion. Our priorities align closely with those of IPE, and we actively support and respond to their initiatives and activities in all aspects of the Corporate Information Transparency Index (CITI) and Climate Action Transparency Index (CATI) evaluation. This partnership has elevated our supply chain sustainability management to a higher level in China, as evidenced by Levi Strauss & Co. consistent top rankings in IPE's annual evaluations. The consistent impressive performance of Levi Strauss & Co. in these evaluations serves as a testament to our unwavering commitment to sustainability.

Indeed, on the journey of sustainable development management, there is no ultimate achievement, only continuous improvement. To surpass our past achievements, we must continually invest in resources. We recognize that in order to reach our strategic goals, it is crucial to adapt our programs to the evolving supply chain landscape. Building upon our work from previous years, we have made further enhancements in the following areas to achieve greater results today and in the future:

• The addition of new personnel and the formation of specialized teams at the group level has facilitated a greater emphasis on strategic goal-setting. As a result, our company is now able to dedicate more attention to executing supply chain-specific projects.

• To enhance efficiency and effectiveness, we have implemented additional improvements and advancements in our self-developed Roadmap tool. This tool has gained further traction and is being actively promoted among our core global apparel and fabric suppliers. It covers more than 70 suppliers (around 140 factories) globally, which represent more than 80% of our global sourcing volume. The aim is to assist each supplier in establishing and monitoring their progress towards carbon and water reduction targets. Through this tool, suppliers are provided with clear and actionable action plans, ensuring a focused approach towards carbon and water reduction.

In particular, we are pleased to report that 12 suppliers (17 factories) in China have successfully finalized their roadmaps and action plans. These suppliers are diligently engaging with their respective business units to foster collaboration and drive supplier action. Effective communication is key to ensuring that synergies are created and sustained throughout the process. In China, 50 suppliers have publicly disclosed their GHG reduction targets, 78 suppliers have publicly disclosed their water reduction targets, and 74 suppliers have publicly disclosed their solid waste reduction targets through IPE PRTR and carbon data sheets.

The use of different tools allows us to better promote and monitor supplier actions in carbon and water reduction, greatly supporting our achievement of the 2025 carbon and water reduction goals in the supply chain. An example of roadmap communication is shown below:

• Globally, through our partnership with the International Finance Corporation (IFC) and Apparel Impact Institute (Aii), we continue to invest resources to help our core global suppliers with carbon and water reduction and related improved business efficiency. We partnered with IFC on the Partnership for Cleaner Textiles (PaCT) and renewable energy (RE) programs in all applicable geographics, as of now, more than 50 wet processing factories participated in PaCT programs. In China, we continuously partnered with the Aii to complete the Carbon Leadership Project (CLP) program in 5 more mills in 2022. Furthermore, in 2022, we initiated a pilot on renewable energy transformation initiative (RETI) in collaboration with Aii China at 5 suppliers in China. The collaboration with Aii helps mills assess the uptake potential of renewable energy sources (project ongoing).

# carbon and water reduction program results, two vendors have made disclosures at IPE: Cone Denim (Jiaxing) Limited and Yixing Lucky Textiles Group Co., Ltd

Of course, our actions on green supply chain management are not only here, because we understand that green supply chain management is multi-dimensional, multi-stakeholder involvement, and a gradual and extended process. We are therefore also making efforts in the following areas:

• Since 2016, the Higg Factory Environmental Module (Higg FEM) platform has played a crucial role in validating environmentally relevant data from factories. This validated data has been instrumental in monitoring and implementing carbon and water reduction and conservation programs at our factories. Additionally, the Higg data has allowed us to assess other areas such as solid waste, enabling us to analyze and establish further reduction targets for our supply chain.

• Sustained active participation to Zero Discharge of Hazardous Chemicals (ZDHC) www.roadmaptozero.com . We continue to be actively involved in the ZDHC program, which reduces pollutants in wastewater by reducing the use of hazardous chemicals. The entire ZDHC approach well compliments to Levi Strauss & Co Screened Chemistry (SC) program. More than 1300 Screened Chemistry-certified chemicals are now used in our supply chain and by some other brands. Levi Strauss & Co. has been recognized by the ZDHC for its effective chemicals management, and has been rated at Aspirational Level for last three consecutive years in the ZDHC Brand to Zero Program.

# Chemicals project results, two suppliers have made disclosures at IPE: Zhongshan Yida Apparel Ltd and Cone Denim (Jiaxing) Limited

• Further deepen the cooperation with the IPE and make full use of the IPE platform to strengthen the environmental management of supply chains in China.

(1) In 2023, more than 133 suppliers in China (covering all categories of products) will be promoted to fill out PRTRs, and more than 103 suppliers in China (covering all categories of products) will be promoted to fill out carbon data sheets. By filling out the Pollutant Emission and Transfer Registration (PRTR) and carbon data sheet, tracking and analyzing supplier carbon and pollutant emission trends, covering 100% of suppliers in China (across all categories) with significant environmental impacts, and mandating suppliers to set corresponding absolute or intensity targets. In addition, through supplier extension management, 16 non LS&Co.’s suppliers were promoted to fill in PRTR data. Furthermore, in 2023, we have successfully promoted a total of 13 factories in Vietnam and Cambodia to report PRTR data.

(2) Through the IPE platform, we not only focus on direct suppliers, but also extend to downstream suppliers such as logistics, chemicals, and wastewater treatment, with over 392 suppliers. This enables us to keep track of the environmental compliance status of wider picture of supply chain in China. We have followed up on a total of 10 environmental violation records of our upstream suppliers in 2023. In 2023, a total of 17 environmental violation records were tracked for various types of suppliers, including 10 records for Levi Strauss & Co. suppliers, 2 records for chemical suppliers upstream, 2 records for hazardous waste disposal vendors upstream, and an additional 3 records from non-LS&Co. suppliers through extended supplier management within our supply chain.

(3) Further promote wider penetration of suppliers to carry out environmental and carbon management of their own supply chains through the IPE platform, expanding to 3 additional fabric suppliers in 2023, building on the previous 5 suppliers.

Levi Strauss & Co. strongly believes that by staying true to the right path, employing scientific methodologies, making continuous investments, fostering multi-party collaboration, and exerting joint efforts, the future of green supply chain management will become even more promising. We are committed to advancing sustainable development and are dedicated to progressing along this path.

Moreover, we will persist in our productive partnership with IPE and eagerly anticipate the opportunities and achievements in the future.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand. This article has both Chinese and English versions. If there is any inconsistency, the Chinese version shall prevail.)