Luxshare Precision adheres to the firm belief in sustainable development and actively responds to global climate actions. We build the Group's sustainable development strategy system around the three dimensions of environment, society and governance, and formulate sustainable development management policies, among which green and low-carbon is the core policy of our environmental management.

We actively identify climate risks and opportunities and formulate climate change strategies and actions. By referring to the recommendations of TCFD, we organize key units highly related to climate risks and opportunities to evaluate and investigate the potential risks and opportunities of upstream, downstream and our own operations and carry out special training on climate change to improve employee’s understanding of the risks and opportunities related to climate change.

We made a public commitment on January 5, 2022, to set carbon reduction targets aligned with the SBTi 1.5°C path and to achieve carbon neutrality by no later than 2050. To achieve these goals, we have steadily advanced action plans for carbon inventory, carbon reduction and carbon neutrality, formulated a roadmap for our climate action plan, and promoted the use of clean energy as the core of our work on energy structure adjustment and low-carbon transformation.

Within the Group, we actively build an efficient, clean, low-carbon and circular green manufacturing system. Through the creation of “Near Zero Carbon Factory”, “Zero Carbon Factory” and “Green Factory”, we have formed a demonstration and leading role to promote the upgrading and acceleration of the construction of the Group's green manufacturing system. Up to now, one of our factories has been awarded the "Near Zero Carbon Factory" title, one factory has passed the PAS2060 declaration and 14 factories have been awarded the "Green Factory" title.

In 2022, through energy-saving transformation projects such as air pressure system/air conditioning system/lighting system, we achieved energy saving of more than 189 million kWh (Air pressure system: leakage detection, vacuum pump replacing vacuum generator, waste heat recovery, pressure division pipeline, loop structure, pipeline decompression, etc. Air conditioning system: constant temperature control, first-level energy efficiency equipment, frequency conversion, DC FFU replacing AC FFU, etc. Lighting system: LED replacing energy-saving lamps, timing switches, illumination management, etc.), and consumed 639,674 MWh of clean energy. Through the above measures, we have achieved reduction of more than 500,000 tons of CO2e, in equivalent to the total amount of CO2 absorbed by nearly 28 million trees in one year and the total amount of CO2 emitted by nearly 110,000 cars in one year, and the amount of investment in emission reduction measures reached 73.5 million yuan.

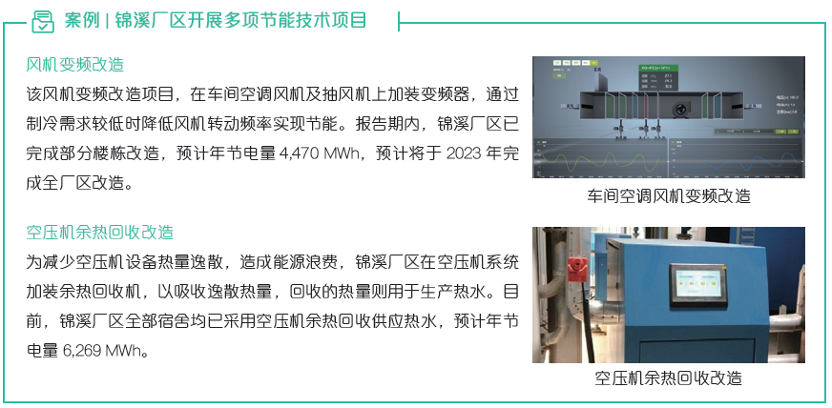

At the same time, we plan to carry out energy-saving projects from 2023 to 2025, achieving 250 million kWh of electricity savings within three years, and achieving a clean energy usage ratio of 50% by 2025. Typical cases of energy saving and efficiency improvement in 2022 are as follows:

Recognizing that supply chain emission reduction is an indispensable and vital part of the value chain to achieve net zero emissions, we have joined the Zero Carbon Supply Chain Initiative at IPE to work with our supply chain partners to promote a zero carbon supply chain. At the same time, drawing on our practical experiences in green and low-carbon operations, we actively engage our supply chain partners to promote emission reduction efforts. In 2023, we set the supply chain emission reduction target to save 100 million kWh energy cumulatively from 2023 to 2025, and provide target progress in the annual sustainability report. We have also developed a Supply Chain Carbon Management System (GSCM platform) where core suppliers report carbon activity data, emission reduction targets and progress tracking.

In addition, through the Institute of Public and Environmental Affairs (IPE) platform, we monitor and manage environmental violations in the supply chain and urge for rectifications.

To date, we have encouraged suppliers to explain and remove 334 violation records, 295 suppliers to disclose PRTR data, and 253 suppliers to disclose carbon data. We also actively guide the secondary suppliers to participate in the IPE project, extend the supply chain environmental management towards upstream, and promote the sustainable development of the entire value chain.

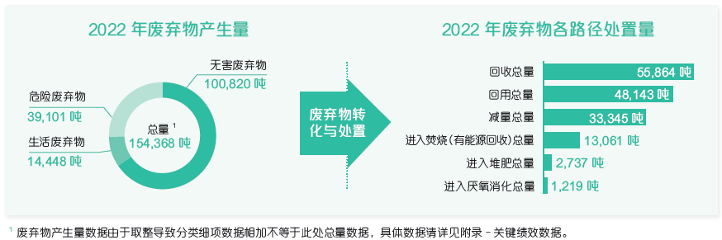

The recycling of resources and the application of different waste disposal methods also contribute to the reduction of emissions in the value chain. Therefore, the Group has launched the "Zero Waste to Landfill" project to improve the utilization rate of waste and reduce environmental pollution. 12 factories have passed the UL2799 Zero Waste to Landfill validation, so that waste can be effectively used. In 2022, the average waste conversion rate of all subsidiaries reached 83%. For waste disposal providers, we use the IPE platform to supervise 12 hazardous waste disposal providers, track the whereabouts and disposal methods of waste, and ensure environmental compliance of hazardous waste disposal providers. We also require disclosure of carbon data and PRTR and other relevant information, and promote the construction of green supply chain together with the supply chain. In the future, we will continue to track the waste reduction performance of the supply chain.

With the promotion of energy conservation and emission reduction work, the transformation of energy structure and the construction of green manufacturing system, we will work together with upstream and downstream partners to move towards the goal of carbon neutrality.

With the promotion of energy conservation and emission reduction work, the transformation of energy structure and the construction of green manufacturing system, we will work together with upstream and downstream partners to move towards the goal of carbon neutrality.