Background

At Nike, we are committed to uniting the world through sport to create a healthy planet, active communities and an equal playing field for all. The understanding that if there is no planet, there is no sport drives our work in sustainability. We believe that protecting the planet will help protect the future of sport for all athletes.

The World Economic Forum identified water crises as one of the top five global risks in terms of impact each year since 2012.[1] We recognize the increasing risk of water availability globally, and have been working to reduce our freshwater footprint, reduce wastewater discharges, and improve wastewater quality to help address these issues and build resilience, both for our business and for the planet.

We are working toward a closed-loop future for water where suppliers can reuse all the water in a circular system. To get there we need our suppliers to focus on resiliency, efficiency and smart management. We collaborate closely with our largest materials suppliers – which represent approximately 80 percent of our global material production – because, through the dyeing and finishing processes, they represent the largest water withdrawals and have the greatest opportunity to improve their water management, wastewater treatment and recycling processes. Five of these material suppliers are located in China.

Nike Minimum Water Programs

In 2016, Nike publicly committed to reducing the amount of freshwater withdrawn per unit of production (L/kg) by these materials suppliers by 20 percent by 2020, measured against a FY16 baseline. To build momentum around water conservation, our global water team deployed the Nike Water Minimum Program to each strategic supplier facility. This program sets performance expectations in three ways:

1. Water management through the creation of site water balance so suppliers can understand where water is going,

2. Collection of wastewater treatment system operational data that enables data-driven continuous improvement to maximize the effectiveness of their existing wastewater treatment system because cleaner wastewater is cheaper and easier to recycle,

3. Understanding the exposure the facility has to water scarcity and flooding risks. If they are located in a region of high risk, this includes developing a water risk mitigation plan.

Besides the Water Minimum Program, Nike also requires each supplier facility to submit freshwater withdrawal and production data each month. Nike uses this data to create a monthly dashboard that is shared with supplier facilities, showing their own progress over time, and how their freshwater efficiency compares with their regional and global peers.

Suppliers participating in the Nike Water Minimum Program are invited to global and regional water meetings, learning communities, and benchmarking visits to peer supplier facilities. At these meetings, suppliers share lessons learned and best practices; and periodically Nike will sponsor outside consultants to provide very specific technical training to help address capability gaps.

Water Recycling

While suppliers zeroed in on achieving their water reduction targets through manufacturing efficiencies, Nike also championed water recycling to reduce freshwater withdrawals and to minimize wastewater discharges to the environment. In 2015, only one of Nike’s five key suppliers in China had plans to recycle dyeing house wastewater. By 2018, all our key suppliers in China installed or were studying the feasibility of wastewater recycling. One of those who installed a wastewater recycling system was the Ramatex facility in Suzhou, China.

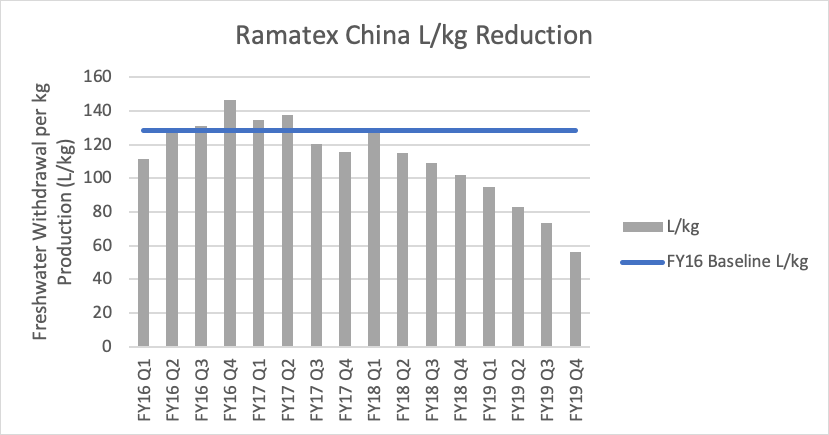

Their recycling system implements commercially-available water treatment equipment, available to anyone. In FY17, Ramatex committed 50 percent freshwater reduction by 2020 by recycling their wastewater. By the end of FY18, their wastewater recycling system was operational and they realized a 40 percent reduction from their baseline. By the end of FY19, with still one more year to go, Ramatex reduced their freshwater withdrawals by 60 percent.

In addition to significantly reducing their freshwater withdrawal and wastewater discharge, Ramatex is also compliant to the ZDHC Wastewater Guideline, the de factowastewater quality standard for the textile industry that goes beyond regulatory compliance by establishing limits on the 183 chemicals on the ZDHC Manufacturer’s Restricted Substances List (MRSL). Beyond the walls of the factory, the efforts at Ramatex are a positive step for nearby Taihu and the surrounding water systems, which for years have been plagued with industrial pollution.

Global Achievement

At the end of FY18, our key material suppliers worldwide, by collaborating with Nike, saved approximately 8.7 billion liters of freshwater, 4.2 billion of which was saved by our key suppliers in China. That reduction put us 68 percent of the way to meeting our commitment of a 20 percent freshwater reduction, with line-of-sight to surpassing our commitment, by the end of FY20.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand)