Background

Nike is targeting a circular future, creating products that last longer and are designed with the end in mind. We focus on sourcing environmentally preferred materials, designing out waste from our products and manufacturing processes, increasing recycling, and converting waste that can’t be recycled into energy. It’s not just good for the planet, it’s good for business too.

Materials represent the largest portion of our environmental footprint, so we continuously work to increase our use of environmentally preferred materials. In FY18, 73% of Nike brand footwear and apparel contained some recycled materials and92% of the rubber used in our products was environmentally preferred.We also continue to innovate the materials we use, reimagining waste in new ways. Flyleather is a good example.

Flyleather is lighter and, based on abrasion testing, is more durable than traditional leather. Creating it has a lower carbon footprint than traditional full grain leather manufacturing. Additionally, because Flyleather is delivered on a roll rather than as hide, it improvescutting efficiency and generates less waste than traditional full-grain leather.

Waste Reduction with Suppliers in China

Since 2002, Nike has worked with contract factories in China to manage and reduce waste in three ways:

§ Introducing management programs to categorize, segregate, and report waste generated.

§ Reducing and recycle waste through process improvements and in-house recycling programs.

§ Recycling scrap into the material that can be used in contract factories.

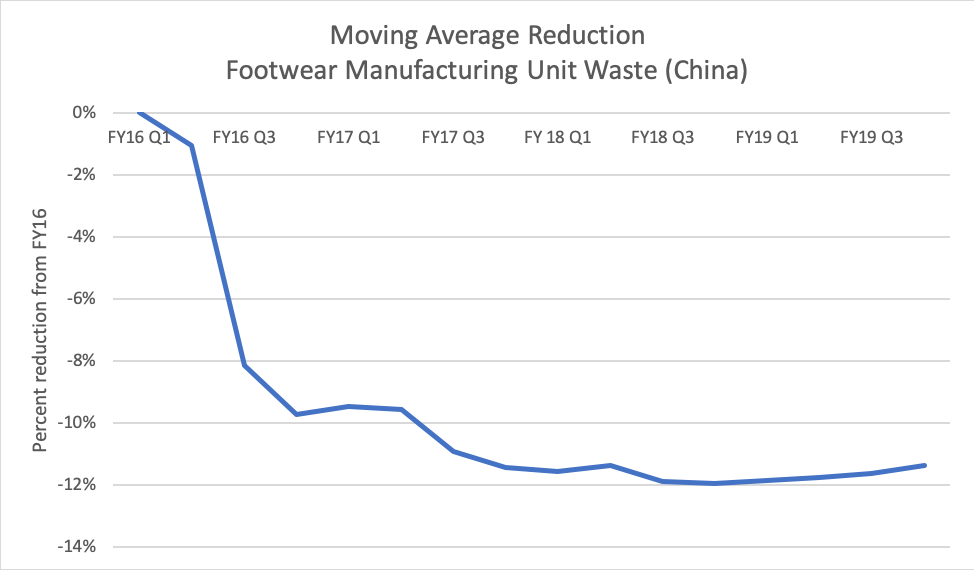

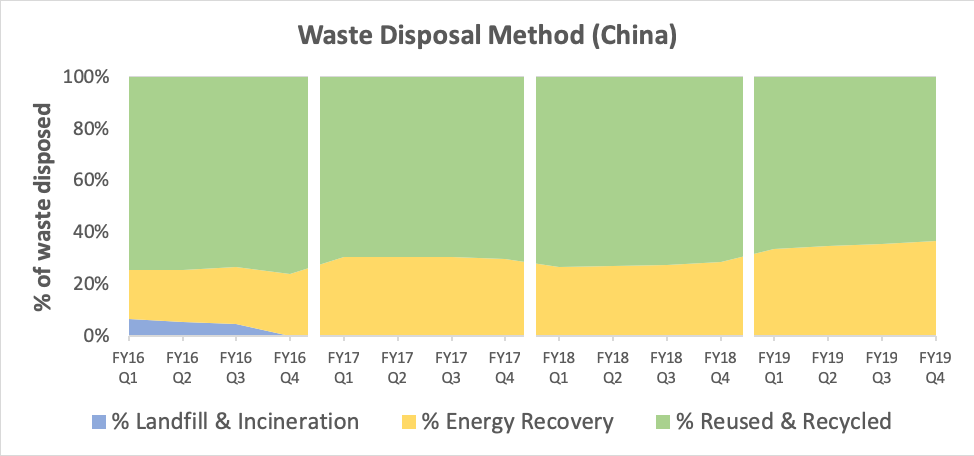

Nike has two 2020 Targets related to waste reduction. First, reducing to zero footwear manufacturing waste to landfill or incineration. Second, reducing waste by 10% in footwear manufacturing. Nike suppliers in China have been leading the way in achieving these goals.

When waste is generated, our contract suppliers in China reuse or recycle itin-house, or use an outside recycler to create new materials. Since FY16, the 13 factories in China that produce Nike and Converse footwear have reduced their collective unit waste by 12%, maintained a recycling rate exceeding 70%, and eliminated all waste to landfill.Over approximately the same time period, they have reused or recycled more than 10 million kilograms of waste back into their manufacturing processes and recycled more than 44 million kilograms into other industries.

Closing the Loop

Numerous types of wastes from our China footwear factories are closed-looprecycled, including various kinds of plastic and cellulosic materials from cutting processes used to make heel and toe reinforcement components, strobels, and lining materials. Corrugated cardboard cartons, plastic and metal drums, thread spools, lasts, and cutting boards are also closed-loop recycled. Collectively, 5-10% of our China footwear factory waste per year has been recycled through these programs– some of which have been operating for more than 17 years.

In the last 5-6 years, our material suppliers have transitioned from closed-loop recycling to what are called “net part” programs. In net part programs, the material manufacturer ships cut parts to the final assembly factory and recycles the cutting scraps in-house. This preserves the original condition of the cutting scraps and avoids the cost, effort, and material loss associated with shipping scrap from the final assembly factory back to the material manufacturer and virtually eliminates waste for these parts.

Nike Grind Program

TheNikeGrindprogram, which just celebrated its 25thanniversary,is another platform that reduces waste to advance closed loop manufacturing. Globally, the program transformsfootwear and surplus manufacturing scrap into a palette of usable materials forhigher value recycling markets. The Nike Grind Program has supplied manufacturing scrap materials–suchasrubberandfoam–tosports surface and flooring manufacturers since 1992,which have been incorporated into more than 1 billion square feet of running tracks, gym floors, and other surfaces worldwide.

TheNikeGrindprogram, which just celebrated its 25thanniversary,is another platform that reduces waste to advance closed loop manufacturing. Globally, the program transformsfootwear and surplus manufacturing scrap into a palette of usable materials forhigher value recycling markets. The Nike Grind Program has supplied manufacturing scrap materials–suchasrubberandfoam–tosports surface and flooring manufacturers since 1992,which have been incorporated into more than 1 billion square feet of running tracks, gym floors, and other surfaces worldwide.

In China we have worked with waste management centers, such as the Future Foam recycling program, for laminated PU foam and the Field Turf program for sports fields. More recently, Nike Grind used in carpet cushioning has diverted approximately 10 million kilograms of footwear waste materials from our contract factories in China since 2012. Building on this success, we are exploring new, non-sport uses for Nike Grind through relationships across the automotive, furniture, and built-environment industries.

Photo: Nike Grind Material from Manufacturing Scrap

Global Achievement

Globally, by the fourth quarter of FY18, 99.9% of Nike’s footwear finished goods manufacturing waste was recycled or converted to energy. This has been accomplished through a comprehensive program including systematic efforts across product design, technology, management oversight and recycling market development.

Nike understands that to truly achieve global and long-lasting change, we need to choose more sustainable materials, design waste out of products, increase material efficiency, partner with contract factories to reduce waste, and create circular markets for waste materials. For more information, please see (Circular design guide link?) and https://purpose.Nike.com/.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand)