In 2015, Apple started engaging directly

with suppliers to find ways to reduce their energy use. Apple aims to promote

continual improvement, build technical capabilities, and increase awareness of

the environmental and financial benefits of energy efficiency.

Apple’s energy efficiency program includes the

following:

• Conducting energy audits: Evaluating the status of energy status at supplier

facilities, identifying opportunities for energy efficiency improvement, and

proposing energy efficiency improvement plans.

• Implementing energy training: Conducting training about energy management for

suppliers. Trainees from these supplier

sites apply their skills and identify and implement additional energy

efficiency projects.

• Supervising energy efficiency projects: Tracking and guiding suppliers on

energy efficiency improvement projects.

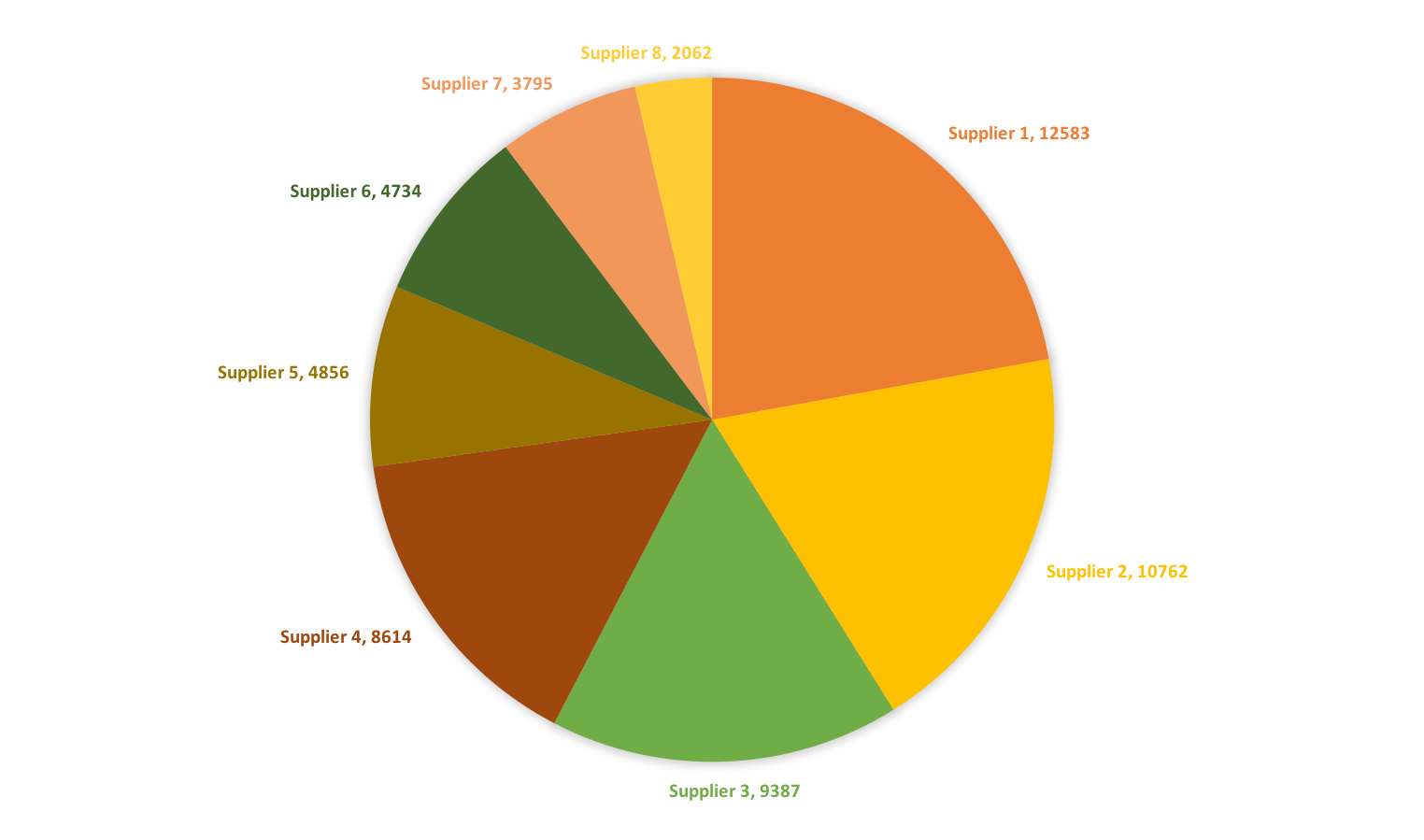

In 2016, the energy efficiency

improvements made by suppliers prevented the discharge of more than 150,000

metric tons of carbon dioxide equivalents (CO2e). The emissions reduction results at China

assembling suppliers are illustrated below:

By participating in Apple’s

Supplier Energy Efficiency Program, one supplier for iPhone assembling

identified multiple ways to reduce energy use, including by replacing outdated and/or

inefficient heating, cooling, and lighting systems; repairing compressed air

leaks; and recovering waste heat. After the project was implemented in 2016,

the supplier reduced its carbon dioxide (CO2) emissions by more than

10,000 tons.

Apple’s efforts go beyond energy

efficiency to spur the development and procurement of renewable energy within the

global supply chain. Apple and suppliers will generate and procure more than four

gigawatts of new clean power worldwide by 2020, including 2 gigawatts in China

alone, and use it to reduce emissions associated with manufacturing.

Up through 2016, Apple has

installed 485 megawatts (MW) of wind and solar projects across six provinces of

China to address upstream emissions that are beyond the influence of Apple’s direct

suppliers. In the province of Inner Mongolia alone, 170MW of solar energy

projects have already been constructed, equating to 230,000 families’ annual electricity

consumption. By grid-connected power generation, these clean energy sources deliver

power to Apple's supply chain in China, replacing traditional thermal power.

Many of Apple’s suppliers in China have made commitments to

100 percent clean energy for Apple production by 2018. One of the participants is

Sunwoda. Sunwoda built a 50 MW solar farm in central Henan Province, China, of

which a portion will supply power to Apple manufacturing. This will lead to a

reduction of more than 60,000 tons of CO2 emissions each year.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)