As one of

the world’s largest retailers, Walmart’s environmental impact extends far

beyond our own operations to the supply chains that deliver apparel,

electronics and other products to our shelves every day. Walmart engages with

our suppliers to reduce these impacts to the environment when possible, with a

focus on energy efficiency.

Walmart

launched the original Factory Energy Efficiency Program in China in 2008 when

the company committed to work with direct suppliers to improve energy

efficiency by 20 percent per unit of production by the end of 2012. After

achieving that goal, Walmart decided to scale the work. In August 2014, Walmart announced

a new commitment for suppliers and factories representing 70 percent of our

business sourced in China to participate in Walmart’s Factory Energy Efficiency

Program by the end of 2017. To achieve this target, Walmart has promoted use of

McKinsey & Company’s Resource Efficiency Deployment Engine (RedE), a

web-based tool designed to help suppliers identify, prioritize and implement

energy efficiency projects in a simple, easy-to-use platform. Factories that

use RedE are provided with project ideas to reduce energy costs, as well as a

platform to track progress and report energy metrics to Walmart.

More than

600 Walmart factories in China are trained on the use of RedE, and participating

factories are supported by local-language training from experts such as

Environmental Defense Fund. Training covers the latest energy efficiency and

renewable technologies, advice on setting up an energy management system, information

on energy policy and best practice sharing. In 2016, more than 200 factories participated

in trainings.

As of February 2017, the program is on track and

delivering results:

- More than 50 percent of our China-sourced business

reports being a part of an energy efficiency program and the company are on

track to meet the 70 percent commitment

- More than 600 factories have joined the RedE

system; on average, an active user is projected to reduce CO2 emissions by 900

metric tons

- More than 650 individual projects are in progress

or complete, driving more than 110,000 metric tons of CO2e emissions

reductions.

(The Walmart Factory Energy Efficiency Program - 50 samples of RedE participating factories’ reported progress.)

Bestway, one of the world’s largest Chinese plastic toy

manufacturers, began participating in Walmart’s Factory Energy Efficiency Program

in 2015. Bestway was encouraged by Walmart to use McKinsey & Company’s

Resource Efficiency Deployment Engine (RedE) to guide the company’s energy

management practice, and measure and report its emissions footprint through the

CDP Supply Chain program.

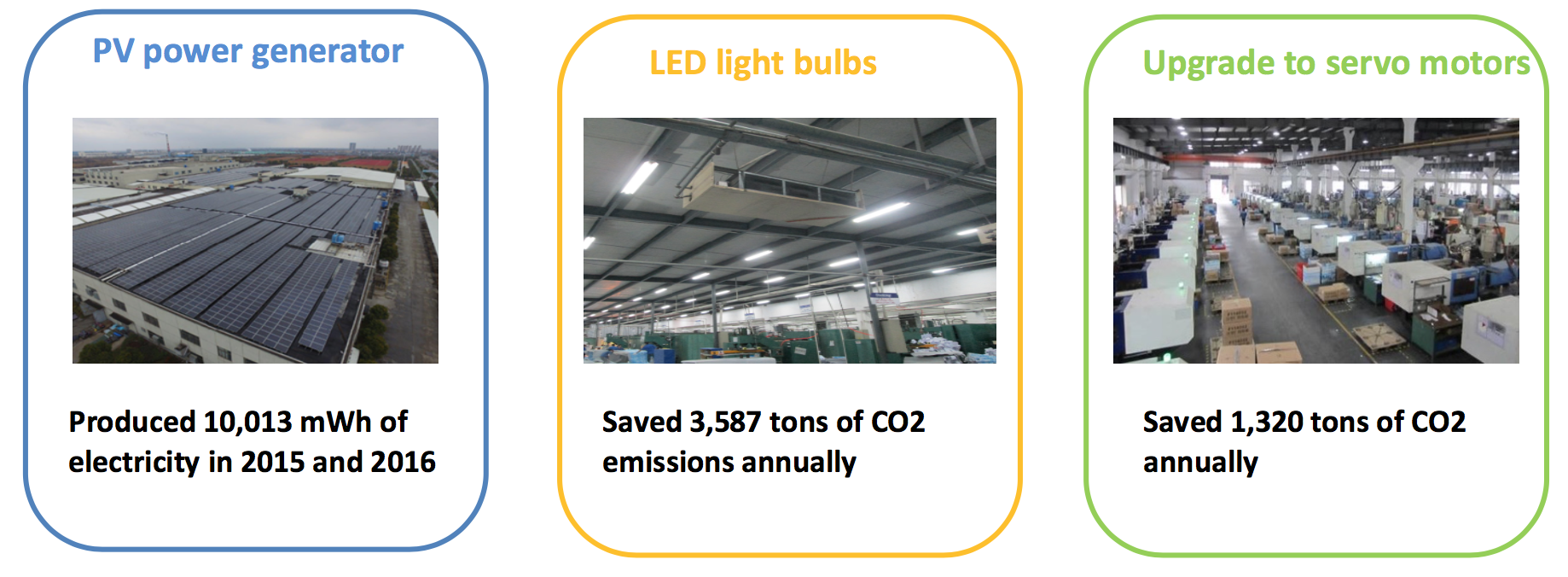

In 2015 and 2016, Bestway implemented 25 projects, which saved nearly

11,000 metric tons of CO2 emissions. Examples of projects implemented include

installing solar panels to generate electricity power, enhancing air compressor

heat recovery systems, recycling and reusing boiler steam, changing to LED

light bulbs and upgrading motors on plastic injection machines. With these

efforts, Bestway was recognized by CDP as a top-rated Chinese company in the

2016-2017 CDP Supply Chain Report.

Bestway took another

step forward in their sustainability efforts by making commitments toward

Walmart’s Project

Gigaton in the areas of energy consumption,

renewable energy and waste; with waste as a new category of reporting and

tracking. Bestway plans to reduce energy consumption by 10% yearly, use 10%

solar for all energy needs by 2020, and increase waste recycling by 3% year

over year.

(The above content was provided to IPE by the brand, who is responsible for the accuracy of the data.)