As almost all of our production is outsourced, a significant part of our environmental impact occurs, at different intensities, throughout the supply chain. Therefore, for Adidas, sourcing is not only about ensuring high quality products and timely delivery, it also means working with our suppliers to ensure they are able to continuously improve their environmental footprint.

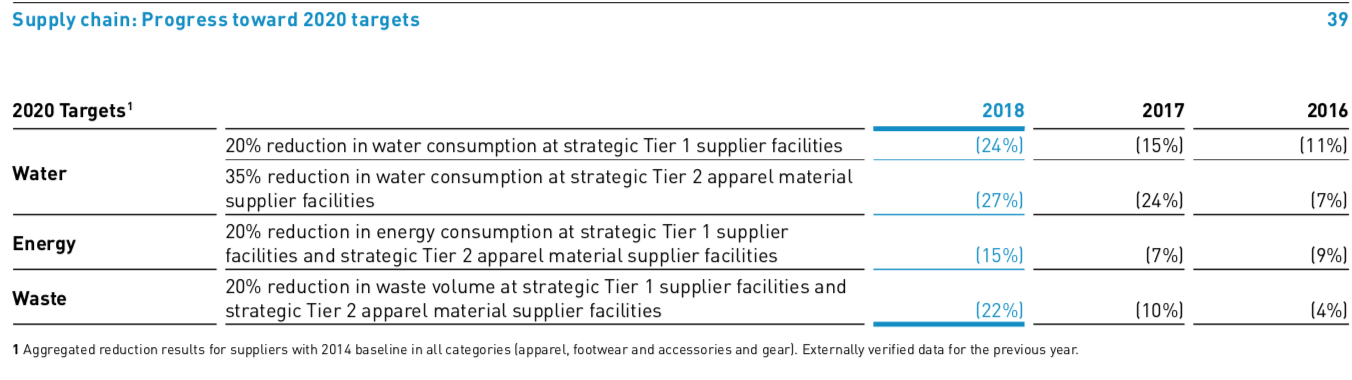

We do so by providing them with policies and best practice guidance for environmental management, by offering training sessions tailored to their needs, and by measuring their progress toward clear reduction targets we expect them to achieve by 2020.

In 2018, we released a newly developed “Environmental Good Practice Guide and Toolkit” to our suppliers. The guide serves as a manual to recommend good industry practices for reducing environmental impacts of manufacturing facility operations. It outlines the adidas approach to the implementation of Environmental Management Systems, data management, wastewater management, and Green Building Management, and provides over 60 saving opportunities on energy, water and waste management and renewable energy.

In 2018, we continued to support a couple of initiatives to accelerate suppliers’ target achievement. We started the “Energy and Water Investment Plan” project with facilities located in five of our main sourcing locations (Cambodia, China, Indonesia, Vietnam and Taiwan) that were off track to achieve their targets or that were recently added to our scope of monitoring. These facilities are required to conduct on-site assessment and develop investment plan enabling them to deliver their energy and water reduction targets.

Factory A, an adidas supplier located in Jiangsu, China, has been implementing a series of saving measures under adidas reduction program.

In 2015, factory A achieved 22,577 GJ energy saving by adopting low-liquor ratio dyeing machines, waste water heat recovery, and solar-powered water pre-heating system.

In 2016, factory A converted the diesel oil boiler into natural gas boiler, which contributes to 31,015 GJ annual energy saving;

In 2017, factory A further realized 8,593 GJ annual energy saving y air compressor system optimization, dyeing machine insulation and steam valve insulation.

In 2018, factory A launched phase 2 of waste water recycle program, achieving over 30% water recycle rate.

In 2019, the clean production project reduced 16.7% energy consumption per sales value compared with 2018.

The above Adidas related content is quoted from Adidas 2018 Annual Reporthttps://report.adidas-group.com/fileadmin/user_upload/adidas_Annual_Report_GB-2018-EN.pdf. Please refer to the original English version if any discrepancy found.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand)