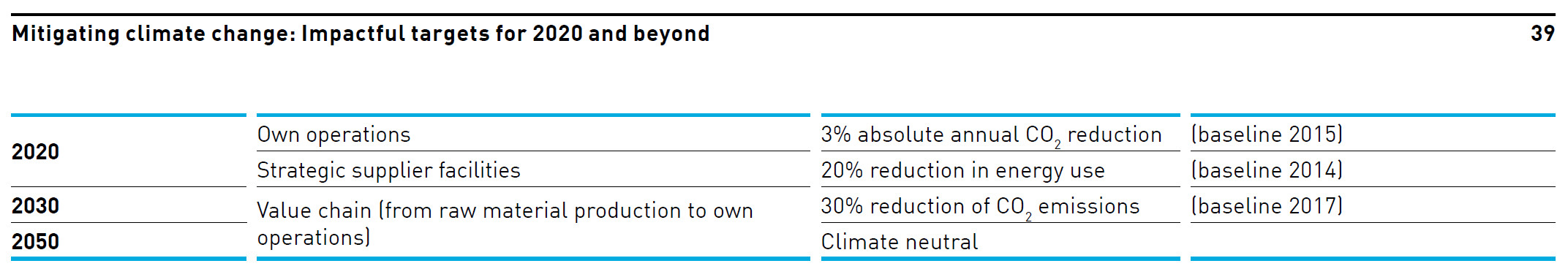

Measuring and optimally managing our environmental footprint in adidas own operations and across our supply chain is one of our ways to respond to climate change. adidas is proactively addressing the impacts of climate change by supporting global initiatives that aims to drive changes in our industry. As a signatory of UN Fashion Industry Charter for Climate Action, adidas has committed to reducing 30% CO2 emissions by 2030 (baseline 2017) that paving the way for climate neutrality by 2050. (See below table)

Since 2010, we have built a robust

environmental program to guide and support our supply chain partners to reduce

environmental footprint collaboratively. In 2015, we’ve further enhanced our program with:

• Monthly

energy data collection to monitor and measure our suppliers’ energy efficiency

performance in a timely manner;

• Annual

data verification to help enhancing data accuracy and reliability.

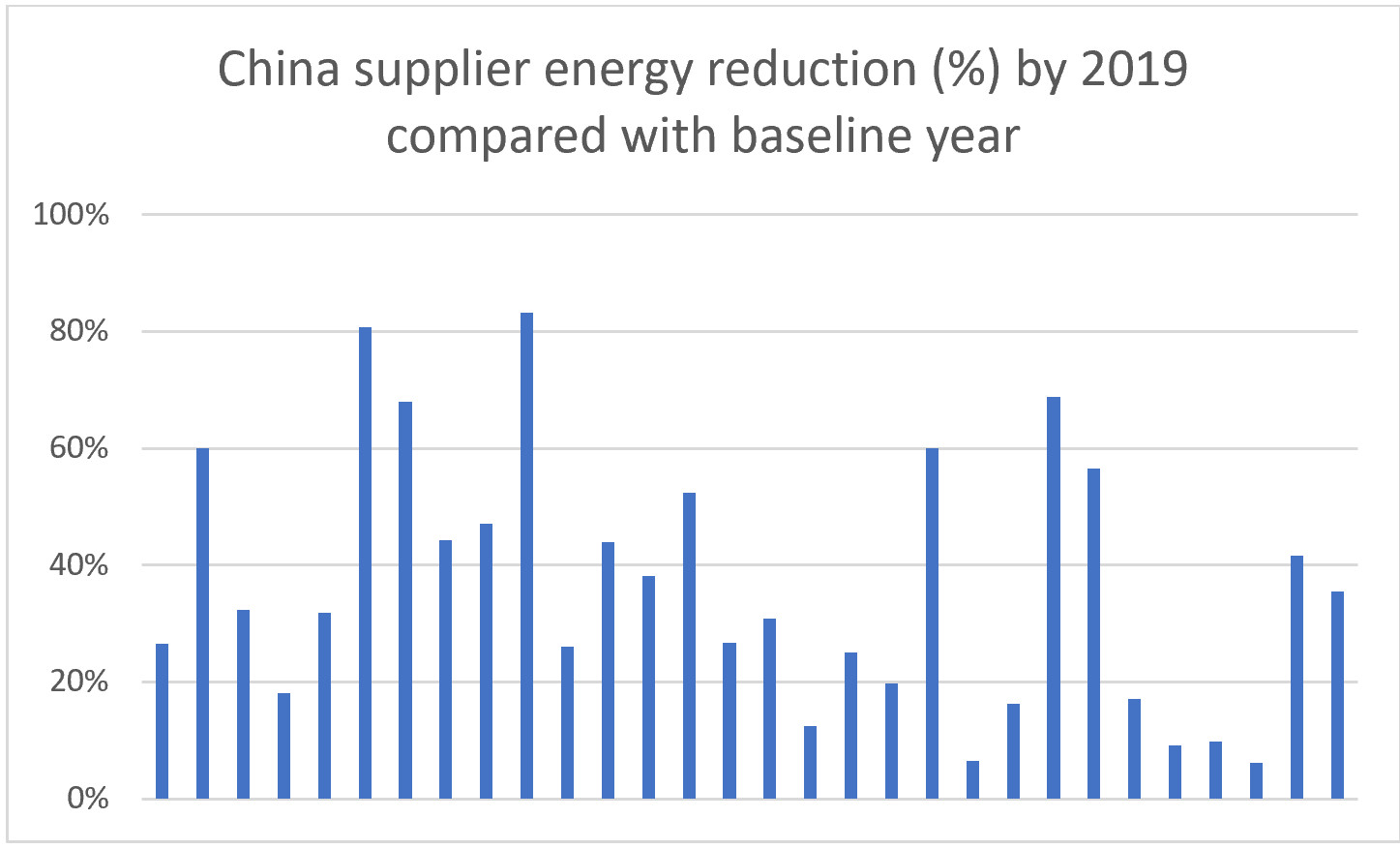

In 2019, our supply chain has surpassed our 2020

energy reduction target (-20% by 2020) and achieved 22% reduction, comparing to

2014 baseline. Around 80% of China suppliers achieved their own energy

reduction target compared with baseline year. It is a result of ongoing efforts to advance suppliers’ capacity for

managing resource efficiency. After the release of the Environmental Good

Practice Guideline and Toolkit in 2018, we updated and issued our Environmental

Guidelines in 2019 for all strategic suppliers, along with an efficiency

calculator so they can better understand their environmental impacts. We

continued to support the Energy and Water Investment Plan and, by the end of

2019, we had mobilized more than 40 strategic suppliers located in five of our

main sourcing locations who

successfully identified more than 400 saving opportunities that will be

implemented with projected annual savings estimated at 350 million MJ of

energy.

We also support our suppliers to gradually

increase the generation and use of renewable energy in our supply chain and

help connect our suppliers with experienced solar companies so they can jointly

work towards the development and implementation of projects. As of 2019, more

than 20% of our strategic suppliers are already adopting renewable energy,

including rooftop solar photovoltaic and biomass. Approximately 12,000 tons of

CO2e has been reduced due to the existing on-site rooftop solar (RTS) systems

in our China supply chain. We understand

the huge potential of CO2 reduction from the on-site RTS system. To further accelerate the renewable energy

adoption in China, we are financing 100% strategic suppliers for the on-site

Rooftop Solar (RTS) Feasibility Study to renewable energy adoption when the RTS

system is not in place to the transition to renewable energy.

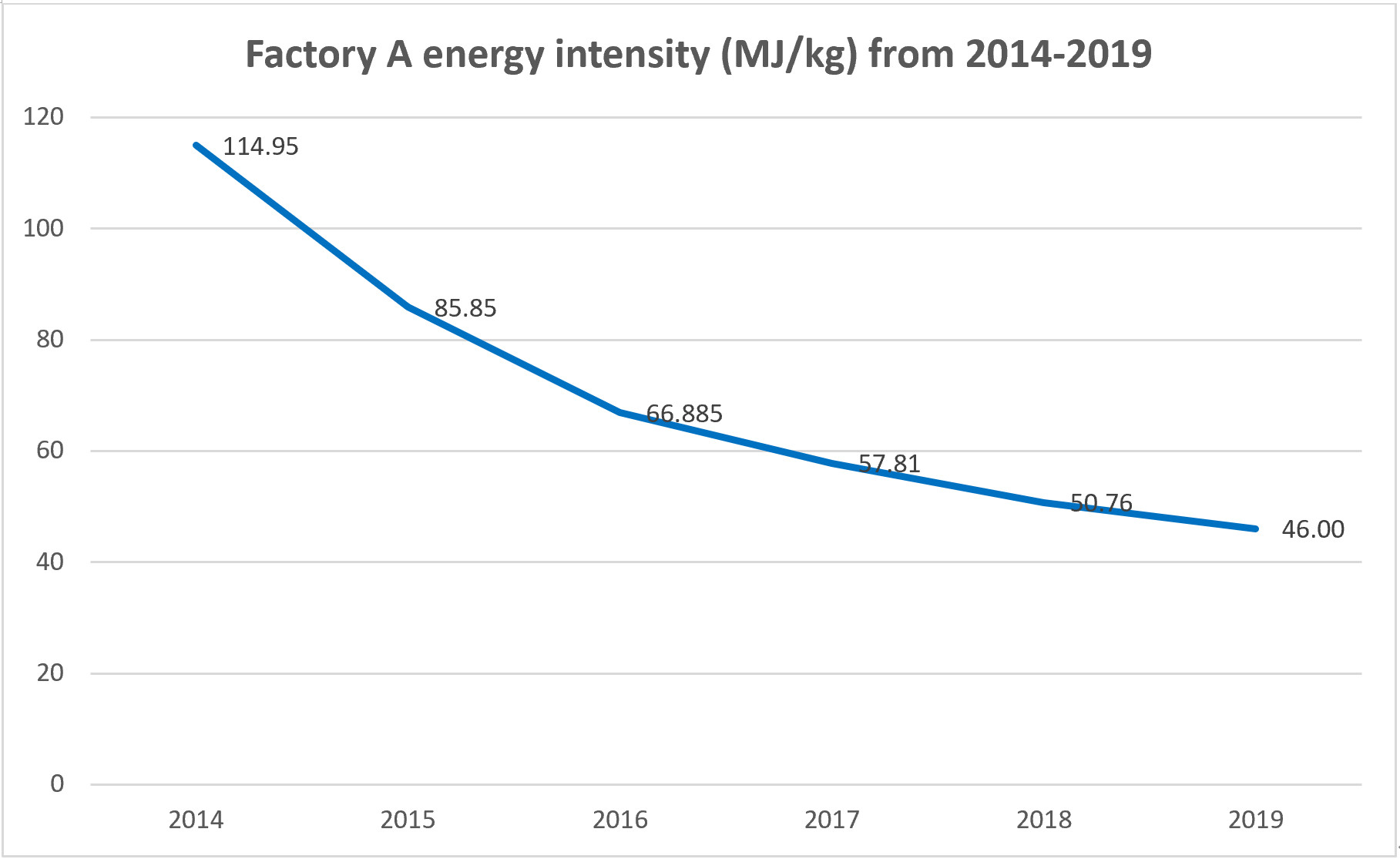

To achieve our carbon emission target, we

are continuously improving our supply chain’s energy efficiency and in parallel

to switch to renewable sources. One of our China suppliers has made significant

progress in reducing energy consumption since 2014, far exceeding their 5%

annual energy reduction target and implemented roof top solar project to reduce

their carbon emission. Below are the energy conservation measures have been

implemented in this China facilities in the past few years:

• 2015:

replaced diesel oil with natural gas and recovered heat from setting machine;

• 2016:

installed rooftop solar system and implemented dyeing machine insulation;

• 2017:

eliminated all on-site boilers and replaced with purchased natural gas;

• 2018-2019:

gradually replaced 80% of low efficient machine and implement lean production

project.

The above adidas related content is mainly quoted from Adidas 2019 Annual Report. Please refer to the original English version if any discrepancy found.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand)