At adidas, we are committed to avoiding the use of restricted substances within our supply chain. We proactively work to prevent the introduction of restricted chemicals into our production processes and strive to minimize the potential release of pollutants into the environment.

To achieve a holistic and responsible commitment, we implement an end-to-end chemical management strategy grounded in the precautionary principle. This includes rigorous oversight of chemical inputs across our manufacturing facilities (Tier 1 and Tier 2), as well as the implementation of strict controls on chemical use and wastewater discharge.

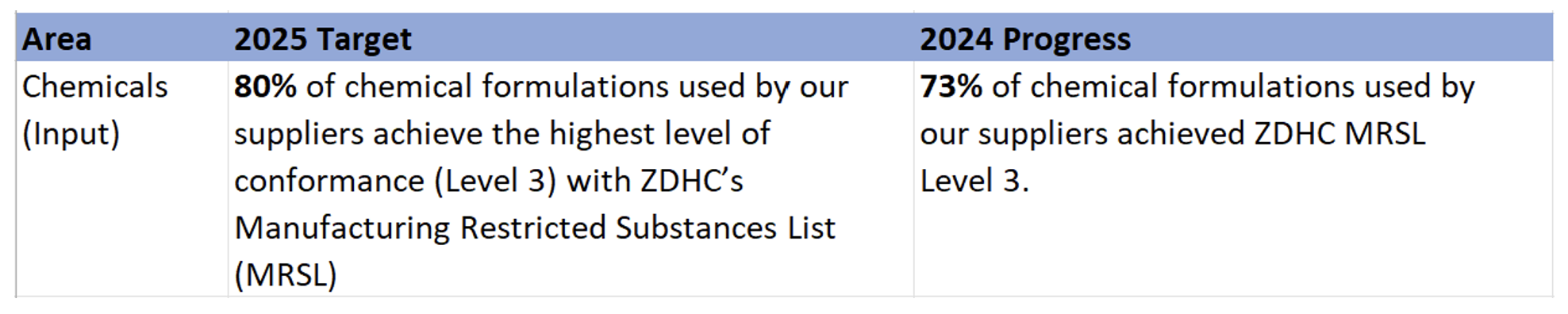

To advance better chemical management across our supply chain, adidas established a five-year strategic roadmap beginning in 2020 aimed at adopting the highest ZDHC MRSL conformance level (Level 3) across our supply chain. By 2025, our goal is to ensure that 80% of chemical formulations used in our production meet ZDHC MRSL Conformance level 3. To achieve this target, we are working closely with our suppliers and implementing a series of responsible chemical practices, including but not limited to:

1)Digitalization of Supply Chain Chemical Inventory Data

adidas initiated digitalization journey in 2021 by implementing BVE3. This digital platform enables real-time monitoring and standardized data collection (chemical inventory data) from Tier 1 and Tier 2 suppliers. As of 2024, we have catalogued approximately 13,188 chemical formulations used in our production processes. To further strengthen data integrity, we incorporated the ZDHC Verified InCheck Level 1 Guideline into our verification process. This guideline was rolled out across our supplier network, resulting in over 80% of suppliers completing on-site Chemical Inventory List (CIL) verifications, with 99% of those achieving performance scores above 80%.

2)Reduction of Unnecessary Chemical Use

With improved visibility in chemical consumption across our supply chain, we identified key opportunities to minimize the use of unnecessary chemicals in our production processes. We conducted a thorough chemical cleansing exercise in our supply chain. This exercise involved identifying and removing non-compliant, obsolete, or infrequently used chemicals from our warehouses to streamline our inventory and reduce waste.

3)Enhancing Performance Through adiformulator program

To close the performance gaps and accelerate progress, the adiFormulator Program was launched in 2023. The strategic initiatives target 40 key chemical formulators.

In tandem, we reinforced our collaboration with bluesign®, promoting the adoption of bluesign®-approved chemicals that align with MRSL Level 3 standards. In 2024, we made significant strides toward this target with 34% increase in chemical formulators reached L3.

4)Eliminating Any Non-Compliant Chemicals in Our Production

To reduce the use of non-compliant chemicals in our supply chain, adidas has taken steps to align with the latest ZDHC MRSL 3.1 requirements. In 2024, ZDHC Responsible Solvents Approach Guide (RSAG) was implemented across our supply chain to guide suppliers in transitioning to safer alternatives by providing the recommendation and how to use the solvents responsibly.

Our 2024 chemical management results are as follows:

For more information, please refer to the LinkedIn post and video for adidas MRSL success story that recognized by ZDHC.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand. This article has both Chinese and English versions. If there is any inconsistency, the Chinese version shall prevail.)