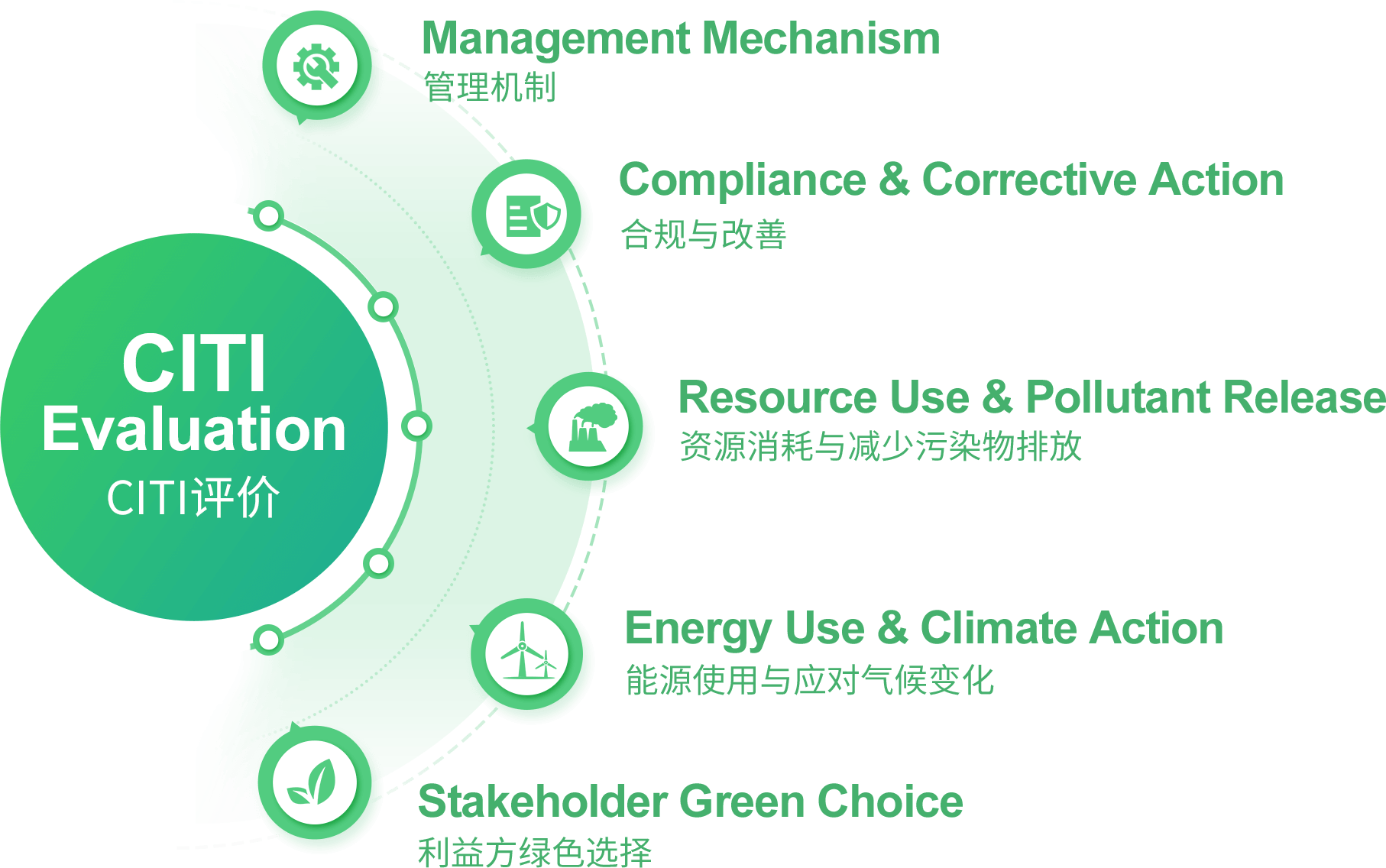

Corporate Climate Action CATI Evaluation

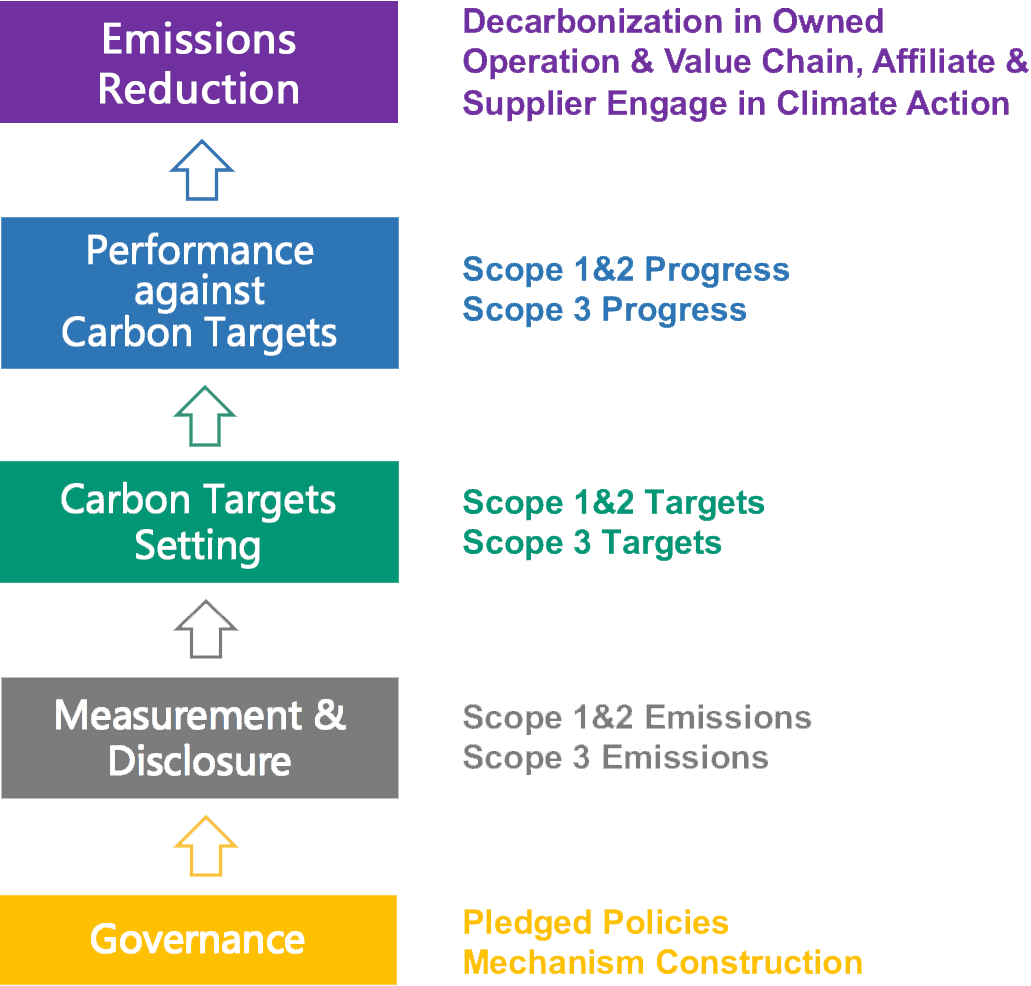

During the "14th Five-Year Plan" period, China’s ecological civilization entered a critical stage focused on carbon reduction as a key strategic direction, aiming to synergize pollution reduction and carbon reduction, facilitate a comprehensive green transformation of economic and social development, and achieve a qualitative improvement in environmental quality. At the same time, an increasing number of multinational companies have made greenhouse gas (GHG) reduction commitments in the post-Paris Agreement era, striving for net-zero emissions across their value chains. In this context, with technical support from the Chinese Research Academy of Environmental Sciences, IPE upgraded the Supply Chain Climate Action Index (SCTI) developed in 2018 to the Corporate Climate Action Index (CATI).

CATI also aims to provide companies with a roadmap to initiate climate action, guiding them to start from greenhouse gas accounting and inventory creation, identify key emission sources, set quantitative emission reduction targets, and develop targeted emission reduction plans. These targets should be broken down into major production processes and the value chain, carry out large-scale emission reductions based on the emission reduction pathways of their industry, track and disclose the progress of target completion, and simultaneously drive and empower upstream and downstream partners to explore the greenhouse gas emission reduction potential at each stage from raw material extraction, production, distribution, storage, use to disposal, and recycling, thereby initiating climate action.

Search the CATI scores for corporations or read the CATI Evaluation Methodology in details.