Foxconn adheres to the operating principle of "sustainable operation=EPS+ESG", which not only focuses on EPS (financial performance), but also its contributions to society, the environment, and corporate governance. Foxconn actively responds to the United Nations Sustainable Development Goals (SDGs) and has joined the CA 100+(Climate Action 100+) initiative to address climate change. It has committed to achieving net zero carbon emissions across its entire value chain by 2050, and supply chain carbon reduction being a critical area requiring long-term efforts.

Foxconn adheres to the concept of "Zero Carbon Transformation and Win-Win Future" with its supply chain partners to meet the ESG supply chain rating indicators of well-known investment rating agencies and the carbon reduction requirements of end customers, and works together to build a low-carbon supply chain. Foxconn empowers its partners to develop sustainable capabilities through three methods: on-site coaching, experience sharing, online training, and performance evaluation.

In 2024, Foxconn selected 10 suppliers based on four dimensions: product category, annual carbon emissions, procurement amount ranking, and manufacturing plant area. An internal expert team was form to carry out on-site coaching work. In order to maximize the impact of energy-saving coaching activities, we have developed on-site coaching execution plans, continuously expanded the scope of supplier empowerment and experience transfer.

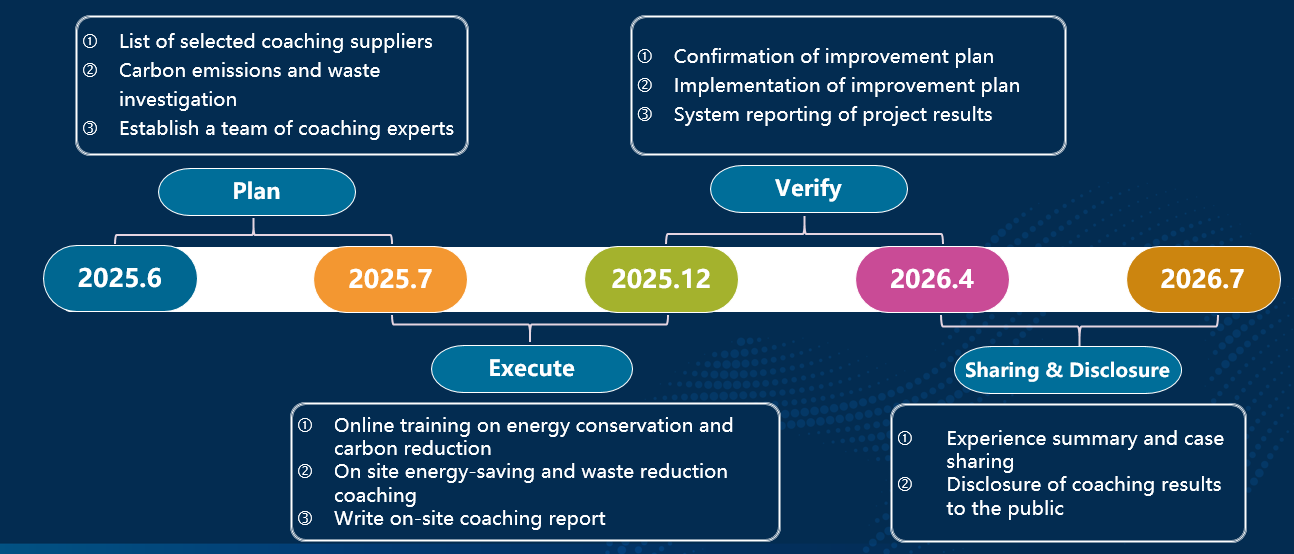

Supplier On-site Coaching Execution Schedule

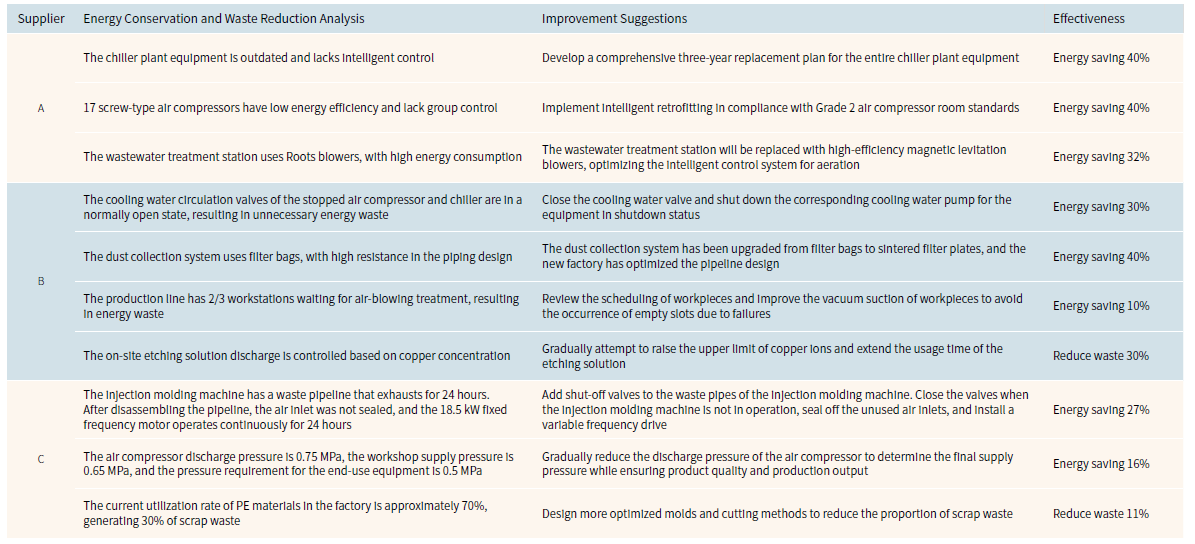

In this coaching activity, the team proposed a total of 61 energy-saving suggestions, of which 43 were accepted and implemented by the suppliers. After the supplier fully implements them, it is expected to save 29.37 million kWh of electricity per year, equivalent to reducing 16749 tons of CO ₂ e. Additionally, 18 waste reduction recommendations were proposed, 13 of which were adopted and implemented.

Suppliers Adopt Energy-saving and Waste Reduction Improvement Suggestions

On May 29, 2025, Foxconn held an experience sharing conference on "Zero Carbon Transformation and Win Win Future", with over 240 suppliers participating. The conference content covers experience sharing of energy-saving projects, innovative management mechanisms, Energy Management Contract (EMC) cooperation models. It aims to consolidate supply chain consensus, jointly exploring ways of energy-saving, low-carbon, and sustainable development.

Due to the large number of suppliers and varying levels of net zero carbon and zero waste management, Foxconn continues to promote the ESG series of online specialized courses and assessments, covering topics such as chemical management, zero waste landfill certification, energy-saving case sharing, scientific carbon reduction target setting, conflict mineral management, and supplier code of conduct. These initiatives aim to strengthen the professional knowledge and practical abilities of suppliers and enhance the overall sustainable execution of the supply chain. Currently, there are seven courses available, such as "Digital Management of Foxconn Carbon Inventory", "Instructions for Promoting Suppliers to Use Green Electricity", "Carbon Reduction Mechanism and Energy saving Case Sharing", and "Summary of Supplier Carbon Reduction and Waste Reduction Coaching", etc. More than 6000 supplier personnel have been empowered to build their capabilities through learning and assessment.

Foxconn will promote online learning and exams for suppliers to be included in the net zero carbon performance evaluation system, requiring suppliers to complete assigned learning tasks and promote courses upstream. This approach to enhance the level of net zero carbon management in the upstream supply chain, empowering suppliers to build sustainable competencies.

Leveraging resources from IPE is another key channel through which Foxconn enhances supplier management capabilities. In 2025, IPE launched three consecutive sessions of online training and empowerment plans, focusing on core issues such as corporate carbon accounting and climate information disclosure, resource consumption and pollutant emission policy interpretation, data-driven intelligent supervision, and chemical substance management. These trainings provide cutting-edge policy insights, practical data management tools, and actionable case analysis for enterprises, promoting them to enhance their environmental management capabilities and compliance levels.

Foxconn actively responded to IPE by mobilizing through multiple channels such as email and social media groups, inviting group suppliers to participate in IPE's online training program. This significantly enhances suppliers' awareness and practical abilities on key issues such as carbon accounting and environmental information disclosure, further strengthening the overall green management and sustainable development of the supply chain. In the future, Foxconn will continue to promote the IPE courses, expand the coverage and influence of training, improve supplier engagement and completion rates, and build a green supply chain capability system for continuous learning.

Foxconn continues to empower suppliers with sustainable capacity building, helping them reduce operating costs and enhance long-term competitiveness through energy efficiency optimization and resource recycling, ultimately achieving net zero carbon emissions.

(The above content is provided by the brand, and the authenticity of the data is the responsibility of the brand)